+86 15633683072

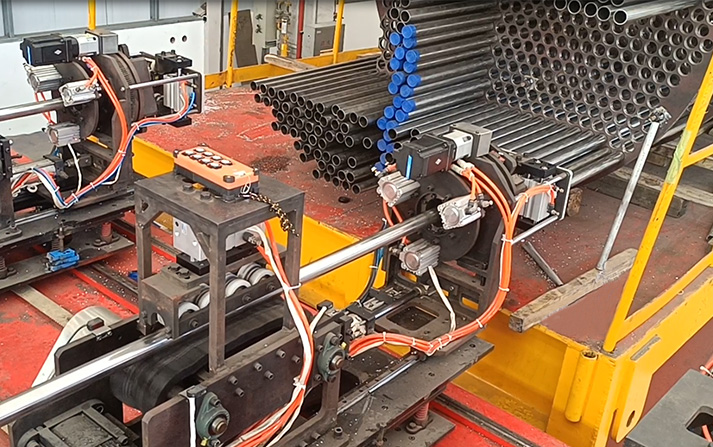

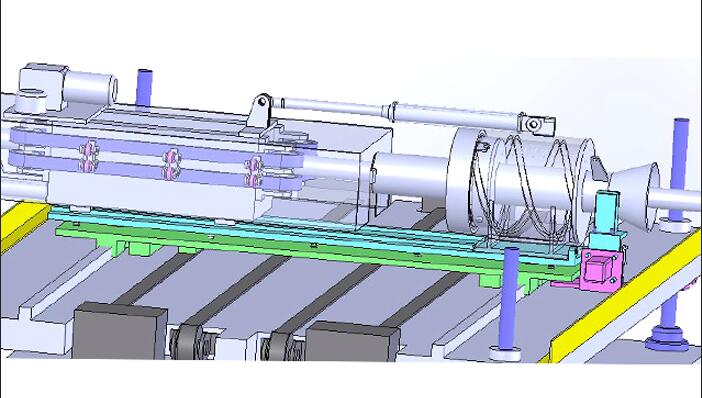

1. Mechanical platform, adopts 4 sets slightly adjustable power heads separately controllered by each groups, to realize the simultaneous penetration of multiple heat exchange pipes, improving tube efficiency, and a set of infrared devices is used to provide an adjustment reference, and the lateral and height data are manually set.

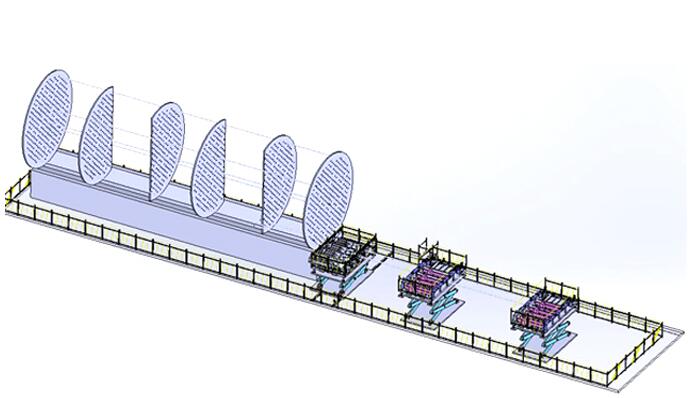

2. Tydraulic lifting platform is with a safety design, including the hydraulic lock stop device, and mechanical platform is equipped with a self-locking device.

3. When pipe automatically assembled, automatic alignment of each hole (the first few need manual assistance) to achieve semi-automatic penetration, and subsequent upgrades according to experience, automatic alignment of the pipe.

4. When assembling the pipes, heat-carrying pipe is automatically penetrated by flexible clamping, which effectively avoids the scratching of the forced pipe or the damage of the heat exchange pipe. And the pipe feeding wheel adopts the beef tendon wheel to ensure heat exchange pipe not damaged, when the side pneumatic device penetrates into the last section.

5. Mechanical pallet designed in the width direction of the platform to avoid excessive deflection when the heat exchange tube is long. In addition, when the pipe head deviation occurs during the pipe assembly process, an alarm device is available, which can be corrected in time.

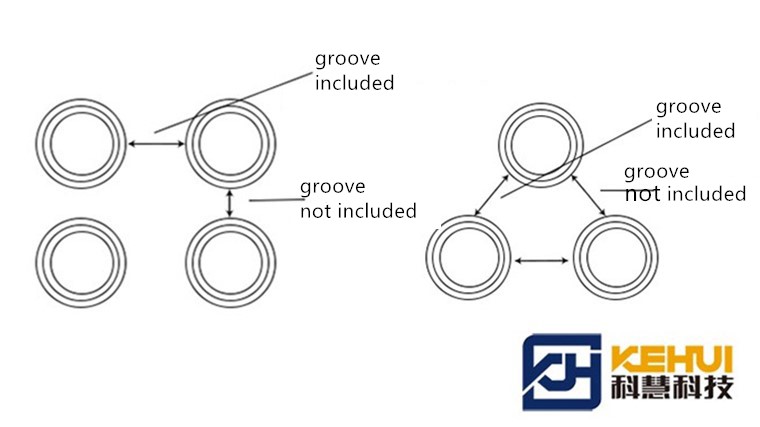

when the square is arranged

when the square is arranged

when the triangle is arranged

Function mode:

manual centering in initial

automatic centering during operation

automatic pipe assembly.

| Stroke parameters | |

| 1st hydraulic lifting platform | 3000*6000mm |

| Lifting height | 5500-6000mm |

| Left and right translation | 4000mm |

| Secondary mechanical lifting | 3000*6000 |

| Lifting height | 1000mm |

| Left and right translation | 4000mm |

| Accuracy | |

| Lifting height positioning accuracy of 1st level hydraulic lifting | 5mm |

| Lifting height positioning accuracy of 2nd level mechanical lifting | 0.5mm |

| Pipes specifications of heat exchanger | |

| Pipe dia. | φ16-φ60mm |

| Pipe wall thickness | 1-5mm |

| Pipe length | 6000-25000mm |

| Other specifications | |

| Gap between hole of tube plate and pipes of heat exchanger | ≤ 0.6mm |

| Pipes extruded length of tube plate | ≤ 8mm |

| Min. length of pipe bridge and tube plate | 3mm when arranged as triangle |

| 3mm when arranged as square | |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com