+86 15633683072

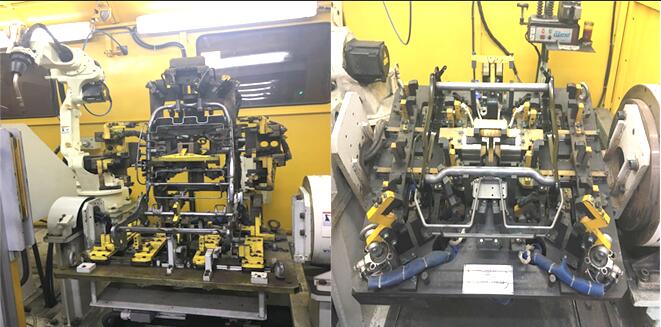

1. The welding unit is simple in configuration and flexible in layout

Can according to the actual situation of the corresponding layout, effectively avoid the interference of the fixture, double-station configuration, flip the machine and fixture, stable and improve the quality of welding, better ensure high quality welding.

2. It is suitable for the welding of workpiece with multiple welds and unconcentrated positions in the mass production of products

Through the turning of the displacement machine and the change of the gun pose of the robot itself, the reactance of the welding gun and the state of the welding gun can be ensured whether the straight line, arc or other complex welds.

3. Double-station layout to improve production efficiency

The double-station layout can effectively prevent the idle time of the robot when the workpiece is disassembled, improve the use efficiency of the robot, and finally improve its production efficiency.

4. Flexible configuration can be customized according to requirements

Can choose the corresponding configuration according to the needs of the product: such as robot system brand.Welding power brand, etc.

5. High flexible strength, reduce product update cycle and save cost

It shortens the preparation period of product upgrade (only need to modify software and necessary fixture, etc.) and reduces the corresponding equipment investment.

6. The fixtures are made of special materials, which are wear-resistant and easy to replace

Fixtures are made of special materials and are heat-treated, making it easy to replace them if they wear out over time.Moreover, the fixture module can be disassembled and replaced with strong flexibility to facilitate the use of other products.

| Number | Project | Parameters |

| 1 | Workpiece Dimension | Can be designed according to the size of the user's workpiece |

| 2 | Workpiece Weight | Can be designed according to user requirements |

| 3 | Welding Speed | Usually take 5~50mm/s, Select according to weld size |

| 4 | Robot Repeats The Positioning Accuracy | ±0.1mm |

| 5 | Moving Mechanism Repeats The Positioning Accuracy | ±0.15mm |

| 6 | Positioning Accuracy Of The Displacement Machine is Repeated | ±0.3 |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com