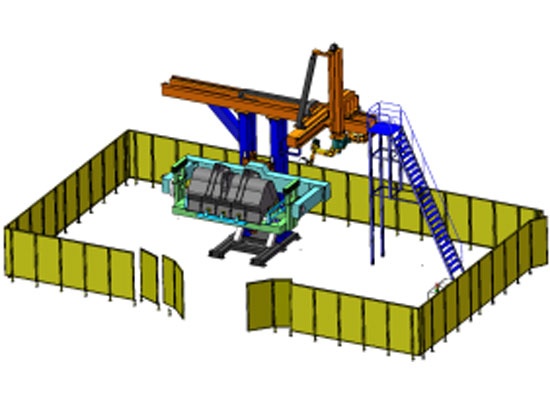

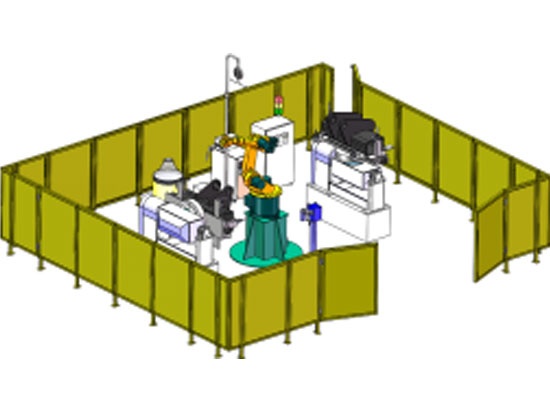

Bulldozer beam and bucket automated collaborative robot welding

The automated collaborative robot welding of bulldozer beams and buckets uses two inverted robots, two sets of fixtures and external walking axes, and adopts dual-machine dual-station operation according to the on-site environment to fully ensure the beat and welding quality, and realize the automated welding of bulldozer beams and buckets. The servo positioner can ensure that the weld is in a stable state as much as possible, which is conducive to the formation of the weld.

Application:

Bulldozer beam and bucket automated collaborative robot welding is widely used in engineering machinery welding, mechanical processing, automobile welding, aerospace, pressure vessel welding, sheet metal processing, chassis cabinet welding, steel structure welding and other industries.