+86 15633683072

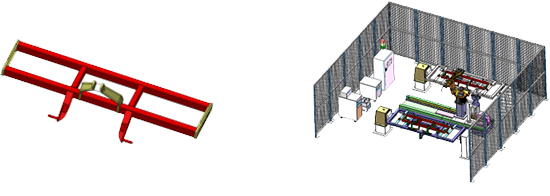

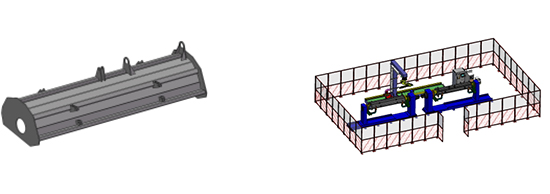

| No. | Items | Parameters |

| 1 | Size of workpieces | Can be designed according to size of workpieces |

| 2 | Weight of workpieces | Can be designed according to requirement |

| 3 | Welding speed | Normally 5 ~ 50mm/s, can be set by weld size |

| 4 | Positional repeatability of robot | ±0.1mm. |

| 5 | Positional repeatability of moving mechanism | ±0.15mm. |

| 6 | Positional repeatability of rotating positioner | ±0.3mm. |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com