+86 15633683072

| Primary power supply | Three-phase AC 380±10% |

| Rated power | 50kVA |

| Secondary maximum short-circuit current | 15000A (under 5% load rate) |

| Electrode maximum pressure | 3000N |

| Welding clamp jaw depth | 350mm |

| Welding clamp electrode stroke | 120mm |

| Maximum weldable workpiece shape | 750*650mm |

| Working height | 850mm |

| Cooling water pressure | 0.20~0.30Mpa |

| Cooling water flow | 20~30L/min |

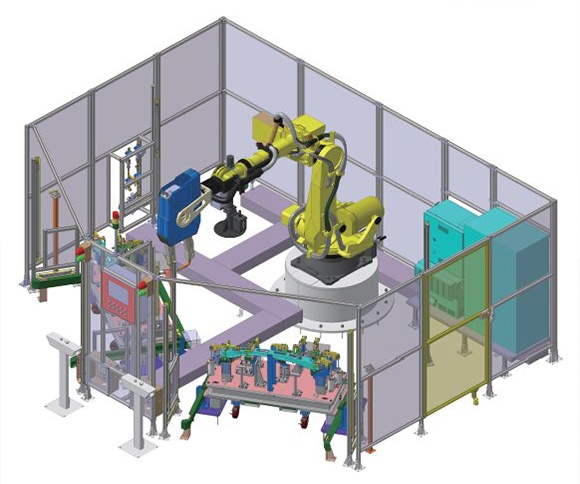

| Robot system (KUKA) | KR150-2 |

| Pneumatic system pressure (MPa) | 0.6 |

| System volume (length×width×height) | 6000×5000×2200 |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com