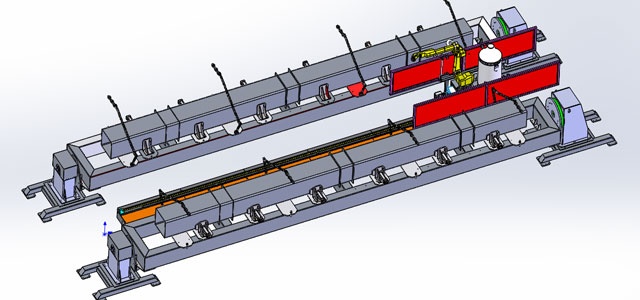

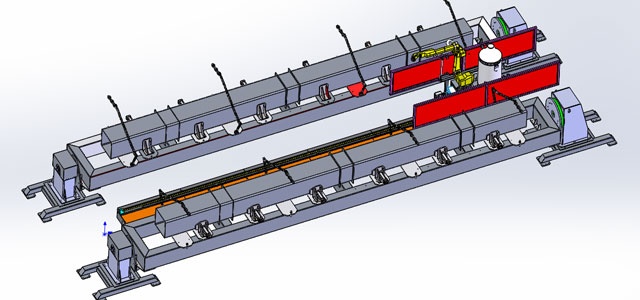

1. Welding fixtures

The fixtures of the production line are designed with automatic clamping and positioning to achieve information interaction with the handling robot. It has a simple structure, convenient operation, high assembly efficiency, and a firm and stable clamping force.

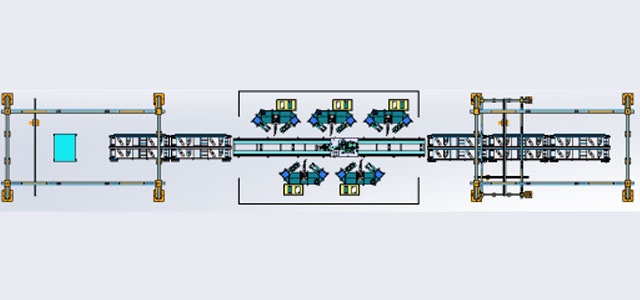

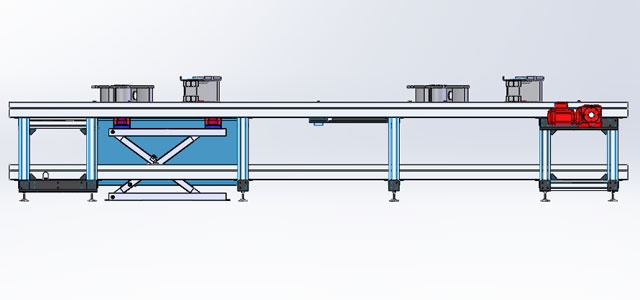

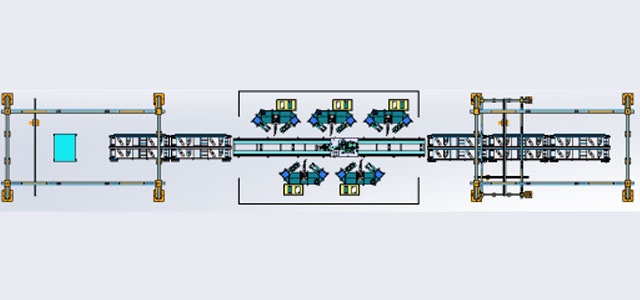

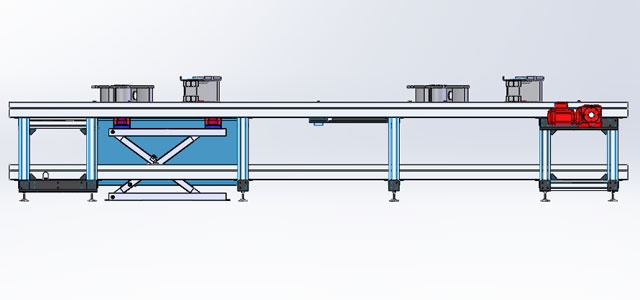

2. Double-speed chain logistics line

A double-layer double-speed chain is used, which is divided into upper and lower layers, and forms a reflux. The workpiece is positioned on the chain plate through the positioning pin, and a secondary positioning mechanism is set in the handling robot docking area to automatically complete the precise positioning of the chain plate.

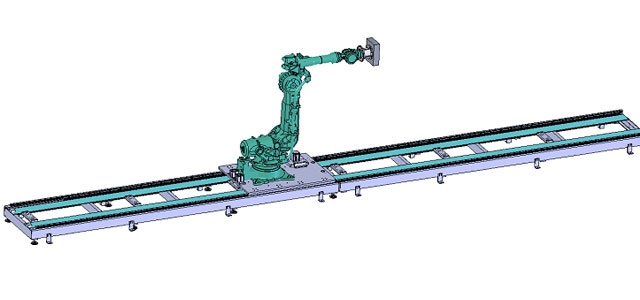

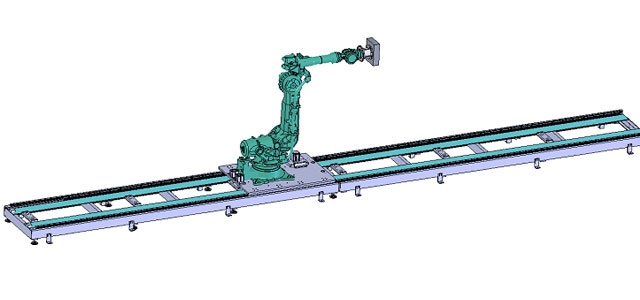

3. Robot slide

The servo motor + precision planetary reducer is used to drive the movement, and it is freely programmable. It uses domestic well-known brand reducers, guide rails, sliders, gear racks, high walking accuracy, meets welding requirements, and has a long service life.

4. Loading and unloading robot logistics line

It is mainly composed of loading and unloading robots, robot control cabinets, robot teaching pendants, 1 set of robot slides, 2 sets of compatible automatic grippers, 2 sets of double-speed chain logistics lines, 1 set of plate chain logistics lines, and 1 set of control systems.

5. Welding line control electrical

A programmable program control system is used, and the main control part is PLC as the main control unit. It has "manual" and "automatic" optional functions, and is equipped with: reservation, power on/off and indication, emergency stop button, mechanical anti-collision, servo anti-collision, power status detection, interference area inspection and other functions.