+86 15633683072

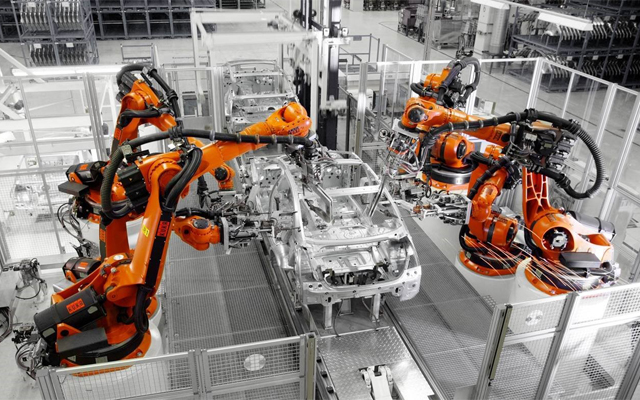

The body shell is a complex structural part welded by thin steel plates. A body is assembled by hundreds of sheet metal stamping parts through positioning welding, gas shielded welding, brazing, bonding and other processes.The welding of automobile body sheet metal parts is carried out in a certain sequence, which has an obvious procedure.Automobile body production process: automobile body parts are transported to the interior of the station by lifting transmission roller bed. After they are in place, the body body welding positioning fixture will clamp the side wall, roof beam and main structure of the body, and then the robot will conduct positioning welding on the body with positioning welding gun.After the welding is finished, the fixture is opened and the body is transported to the next station by the lifting roller bed.Automatic welding line is often used in the body section.

In order to monitor the geometric precision of the vehicle body in real time, on-line measurement is usually adopted in the main line.The online measurement is to use laser technology to make geometric measurement of the car body, compare the measurement data with the standard data and feedback the comparison results.Thus, the geometric precision of the car body can be monitored by 100%.The on-line measurement is divided into robot type and fixed side head type.The robot type is suitable for collinear multi-model measurement, and the fixed side head type has high precision, but generally only for one model.

Main line 3 mainly completes the welding of the canopy.Some of the roof welding resistance location welding, but the more advanced technology is laser brazing.Brazing is a welding method in which the filler with a melting point lower than that of the welded metal fills the gap of the weld by capillary action after melting and diffuses with the wire.The main difference between brazing and fusion welding is that in brazing only the filler metal melts, while the welded metal does not melt (the welded metal melts in fusion welding). The liquid filler metal enters the gap between the two welds by wetting and capillary action, and the atomic bonding is achieved by the mutual diffusion of the liquid filler metal and the solid metal.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com