+86 15633683072

Certifications

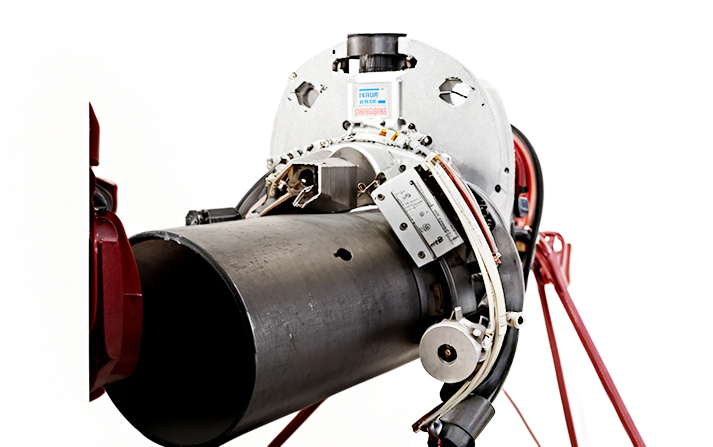

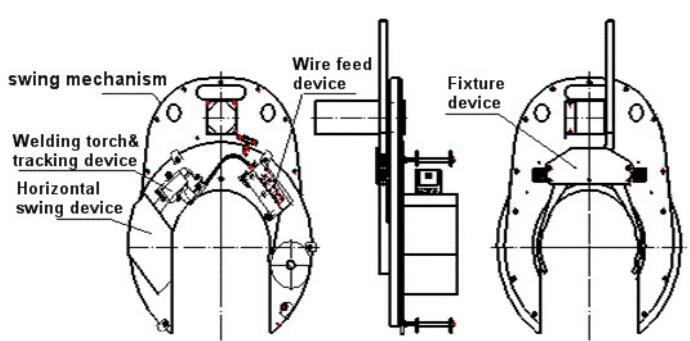

| Welding head | KHGK16-40 | KHGK36-90 | KHGK70-160 | KHGK140-230 | KHGK210-300 | ||||

| Welding Speed(r/min) | 0.4~3 | 0.2~2 | 0.1~1 | 0.07~0.5 | 0.07~0.5 | ||||

| Suitable Dia.(mm) | 16~40 | 36~90 | 70~160 | 140~230 | 210~300 | ||||

| Electrode Dia.(mm) | 1.6/2.4 | 2.4 | 2.4 | 2.4 | 2.4 | ||||

| Swinging function (OSC function) | |||||||||

| Amplitude(mm) | --- | ±8 | ±8 | ±8 | ±8 | ||||

| Speed(mm/s) | --- | 0.5~10 | 0.5~10 | 0.5~10 | 0.5~10 | ||||

| Dwell time(s) | --- | 0.1~10 | 0.1~10 | 0.1~10 | 0.1~10 | ||||

| Arc Voltage Control (AVC function) | |||||||||

| Amplitude(mm) | --- | 8 | 8 | 8 | 8 | ||||

| Speed(mm/s) | --- | 2.5 | 2.5 | 2.5 | 2.5 | ||||

| Filler Wire | |||||||||

| Wire Dia.(mm) | 0.8/1.0 | 0.8/1.0 | 0.8/1.0 | 0.8/1.0 | 0.8/1.0 | ||||

| Speed(mm/min) | 0~1500 | 0~1500 | 0~1500 | 0~1500 | 0~1500 | ||||

| Welding Torch | |||||||||

| Adjust Angle of welding torch | 0°~45° | 0°~45° | 0°~45° | 0°~45° | 0°~45° | ||||

| Rated input voltage | 380V±10% |

| Rated welding voltage | TIG welding, 22.6V |

| Phase number | three-phase |

| Rated power input | 13.2KW |

| Argon flow | 8~12L/min |

| Rated voltage no-load | 70V |

| Frequency | 50/60HZ |

| Welding current adjusting range | 4~400A |

| Voltage allow fluctuating range | 380V±10% |

| Rated duty cycle | 400A 60% |

| 250A 100% | |

| Rated input capacity | 13.9KVA |

| Built-in memory space | 100 groups of welding code |

| Each set can segments | 1~12 section |

| Pulse frequency | 0.5~500HZ |

| Preheating time | 0.1~25S |

| Current rise time | 0.1~25S |

| Current decrease time | 0.1~25S |

| Cooling water pressure | 1.2kgf/㎡ |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com