China Handheld Laser Welding Machine

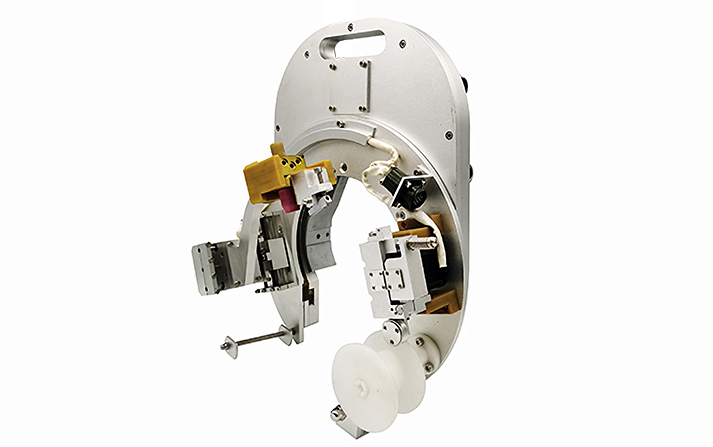

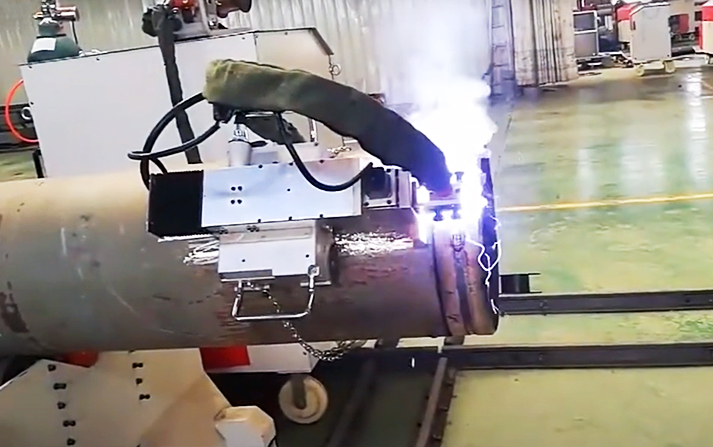

This China handheld laser welding machine uses a famous brand laser source, which is highly stable, power-saving, and basically maintenance-free, effectively reducing the cost of equipment use and optimizing user experience. The full-screen operation interface shows the working status at a glance, and the settings are simple and easy to learn. The welding is firm, the welding speed is fast, and the weld is smooth and uniform. According to your processing needs, spot welding, straight seam welding, lap welding, ring welding and arbitrary orbital welding can be achieved.