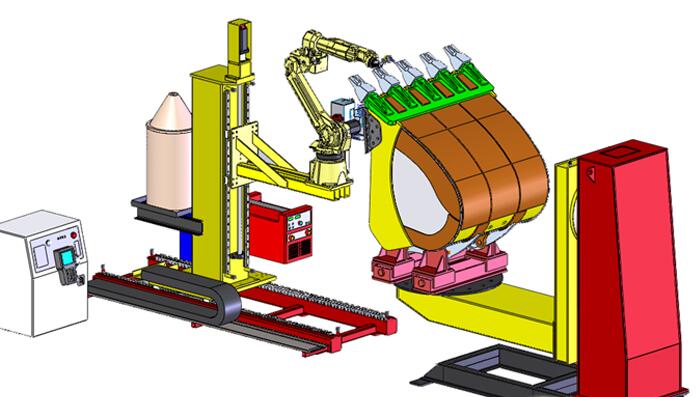

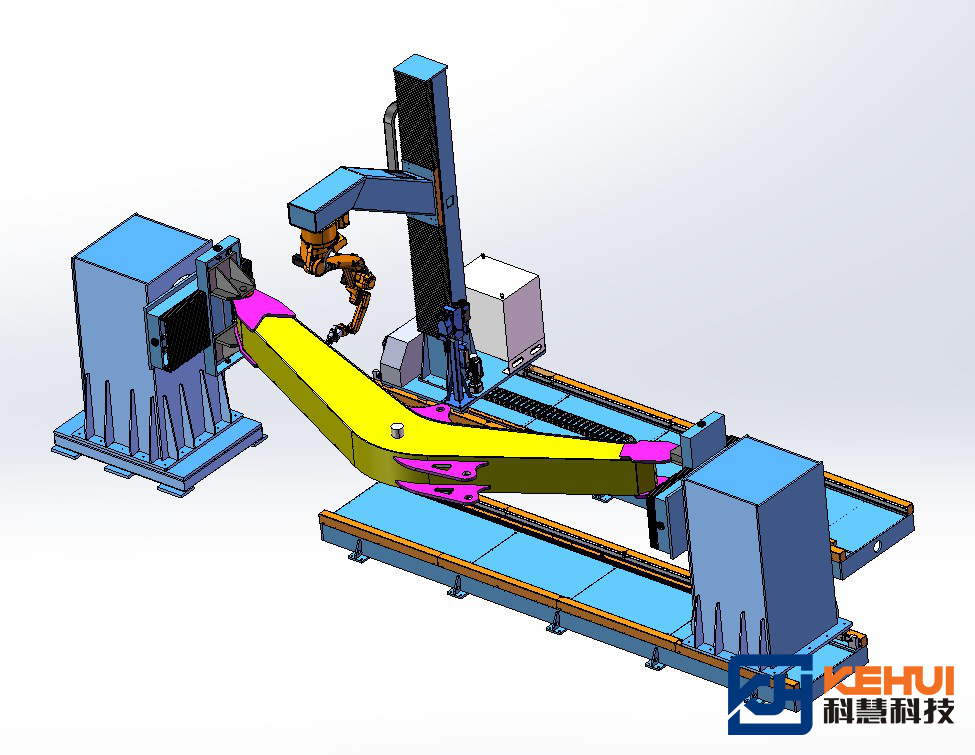

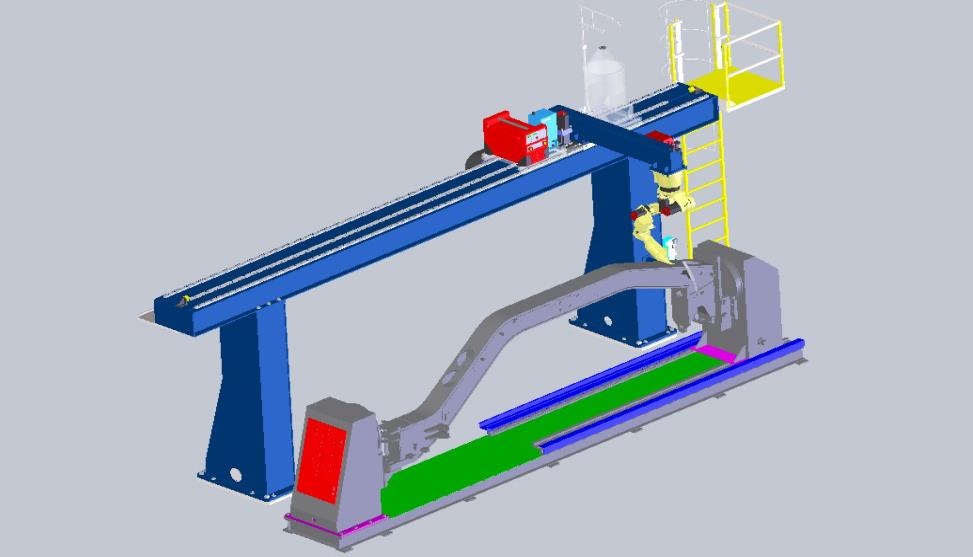

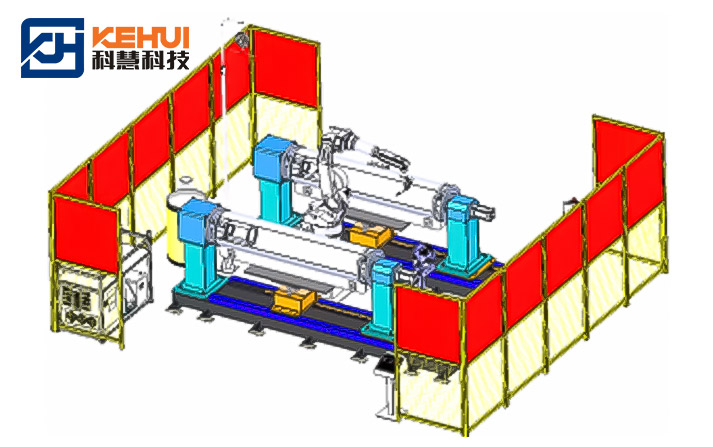

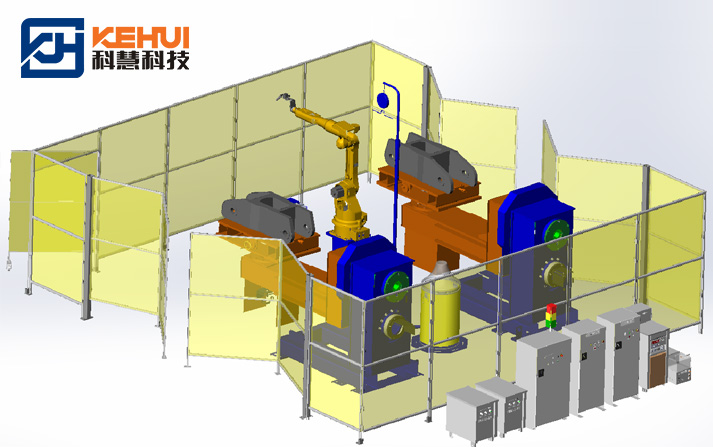

Truck Crane Robot Laser Welding Workstation

The truck crane robot laser welding workstation has flexible layout and various forms. It can be laid out according to the actual situation for welding different workpieces. It is suitable for welding tasks at the turntable, hoist box, X-frame, arm head, turntable seat ring, rear frame and other positions of the truck crane. The Truck crane robot laser welding workstation adopts advanced visual sensing technology, arc sensing technology, coordinate conversion technology and dynamic compensation technology, and has made comprehensive intelligent adjustments in the overall framework, mechanical transmission of the equipment, overall control accuracy, online control of welding quality, and coordination with peripheral equipment and environment.