+86 15633683072

As a highly automated welding equipment, orbital welding machine is widely used in pipelines, aerospace, chemical industry, food processing and other fields. It is known for its high precision, welding consistency and efficient working capabilities. However, the prices of orbital welding machines on the market vary greatly, ranging from tens of thousands to hundreds of thousands of yuan. So, what factors account for these price differences? How should companies weigh price and performance when choosing to purchase? This article will analyze the determinants of orbital welding machine price from several main aspects.

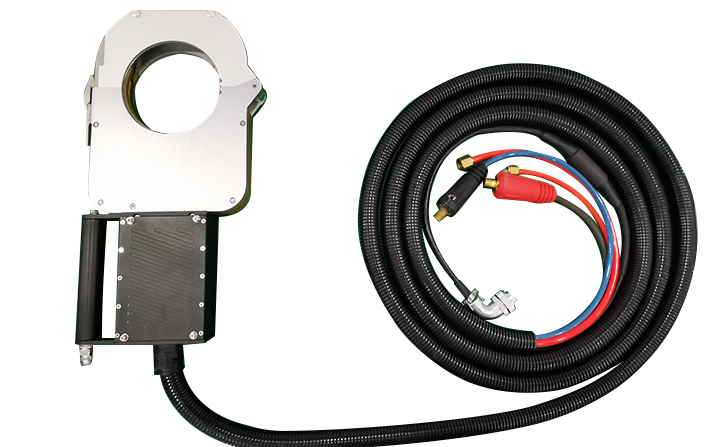

Caliper type pipe welding machine

Closed pipe welding machine

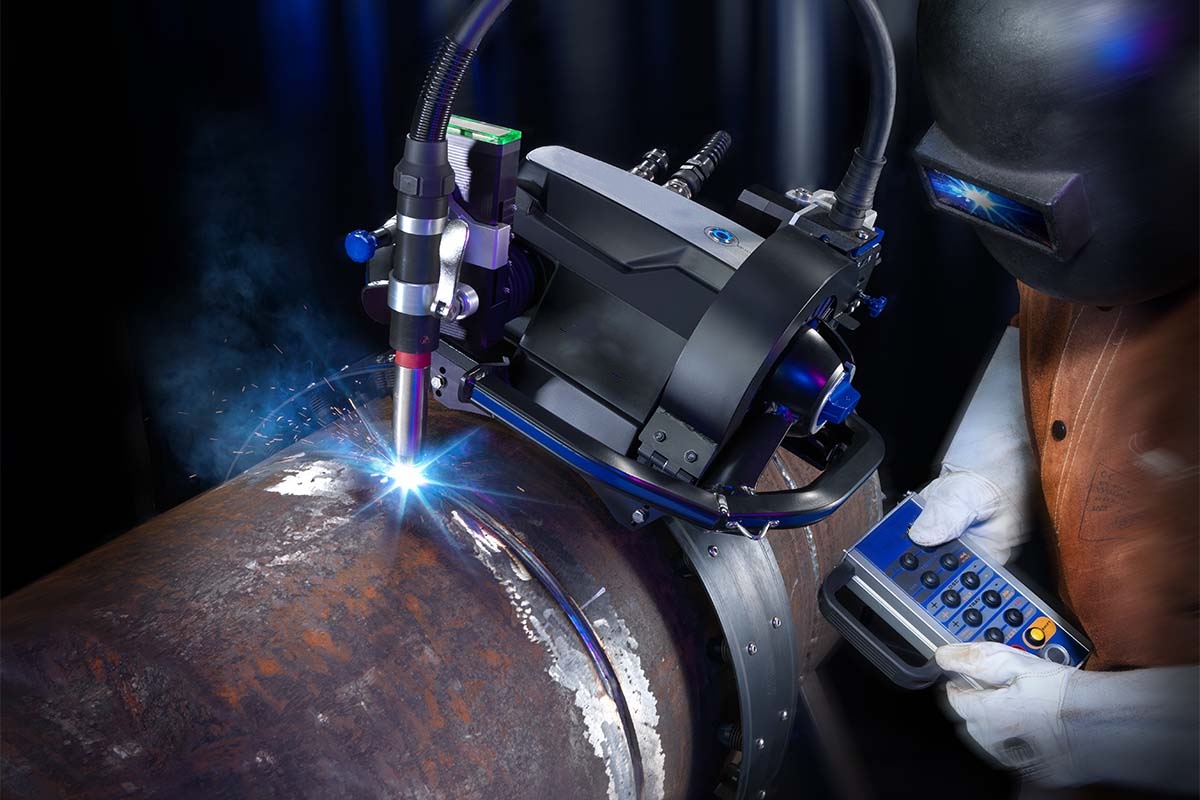

Magnetic track crawling orbital welding machine

Tube to tubesheet welding machine

The technical level of an orbital welding machine is one of the key factors affecting its price. High-end orbital welding machines usually integrate more intelligent functions, such as automatically adjusting current, voltage, welding speed, etc., to adapt to the welding needs of pipes of different materials and thicknesses. This type of pipe welding machine usually also has a memory function, which can store multiple welding procedures to reduce human intervention and thereby improve production efficiency.

Relatively speaking, low-priced orbital welding machines have relatively single functions and are suitable for certain specific welding scenarios. Although this type of equipment is not as comprehensive in functionality as high-end models, it still has certain application value in low technical requirements or in mass production. When companies make choices, they need to decide whether they need to invest in high-priced equipment based on their actual welding needs. If an enterprise is pursuing high-precision welding and long-term production efficiency, high-end equipment may be more cost-effective.

Brand is another important factor that affects price. Orbital welding machines of internationally renowned brands are usually more expensive, but these equipment often have significant advantages in technological maturity, equipment stability and after-sales service. For example, welding machines from Europe and the United States are known for their high quality and durability and can handle complex and high-precision welding tasks, but they are very expensive.

At the same time, with the development of technology globalization, the orbital welding machines developed by many Chinese welding machine manufacturers have gradually caught up with the international level in terms of functions and performance, and the prices are relatively low. This type of equipment is suitable for companies with a limited budget but still want to increase the level of welding automation. In addition, welding machine manufacturers from China are often more competitive in terms of after-sales service, especially market response speed and maintenance costs.

Orbital welding machine price is also closely related to its application fields. Equipment used in the nuclear industry, aerospace and other fields usually require higher welding precision and stricter quality control, which means manufacturers need to invest more in equipment design, material selection and technology research and development, which naturally pushes up the price of the equipment.

On the other hand, some orbital welding machines need to be customized according to customers' special needs, such as pipe specifications, welding processes, control systems, etc. The price of such customized pipe welding equipment will be much higher than standard equipment. Therefore, enterprises must fully consider the application environment of the equipment when purchasing and evaluate whether customized solutions are needed.

Orbital welding machine price is affected by many factors, including technical level, brand, application field and customization needs. When enterprises choose equipment, they need to comprehensively consider the cost-effectiveness, long-term return on investment and market trends of the equipment based on their own needs and budget. No matter what price range of pipe welding machine you choose, only by making economic decisions suitable for the development of your enterprise can you remain invincible in the fiercely competitive market.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com