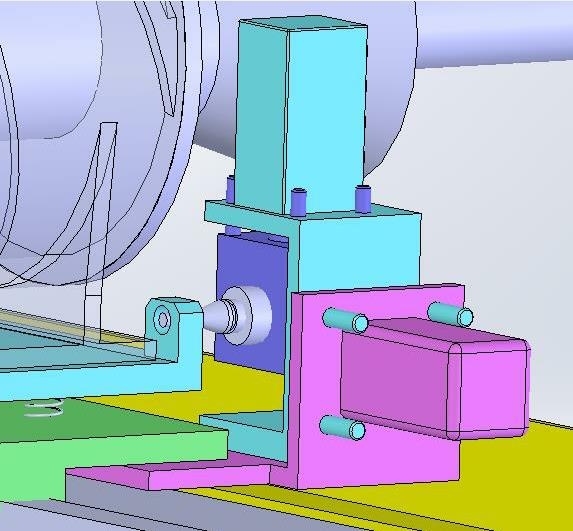

Automatic pipe threading system for heat exchanger welding robotic assembly line

The automatic pipe threading system for heat exchanger welding robotic assembly line adopts a modular method with 3 groups of modules separated, which is suitable for pipe threading operation of large diameter heat exchangers (less than φ8000). The device has an automatic lifting function. The heat exchange tube is automatically lifted and transported from the main lifting platform to the secondary fine-tuning lifting platform to automatically complete the function of threading the heat exchange tube. The platform is divided into a primary platform and a secondary platform. The primary platform is the main lifting platform, and the secondary platform has a height fine-tuning function and a left and right movement function - mainly used for the centering of the heat exchange tube and the tube sheet hole.

Application:

The welding robotic assembly line of the heat exchanger automatic threading system is widely used in the automatic welding of the heat exchange tube threading system of large-diameter heat exchangers (less than φ8000mm). The device has an automatic lifting function module and a heat exchange tube automatic threading function module. It realizes the functions of automatic tube feeding, position adjustment and automatic threading.