+86 15633683072

Arc welding robots are not just mechanical arms performing repetitive movements.In modern manufacturing, arc welding robots are the result of two deeply integrated technologies working together to deliver accuracy, consistency, and productivity.

To truly understand arc welding in robotics, we need to look beyond the robot itself and focus on the core technologies that make arc welding automation reliable on a real production floor.

The first integrated technology behind arc welding robots is advanced robotic motion control.

Unlike simple point-to-point automation, arc welding in robotics requires continuous-path motion with strict control over:

Travel speed

Torch angle and orientation

Arc length stability

Synchronization with positioners or tracks

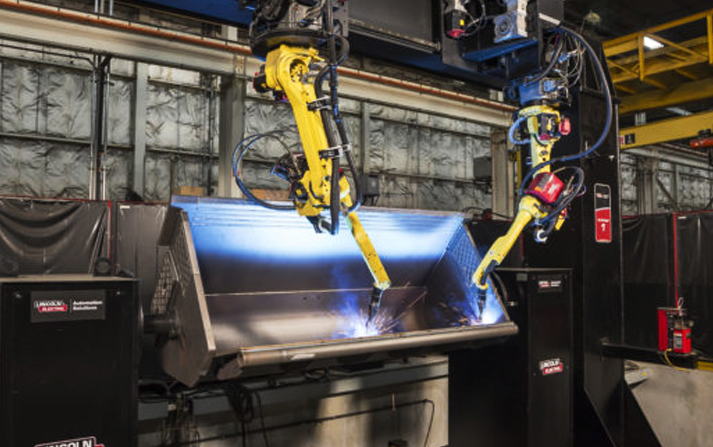

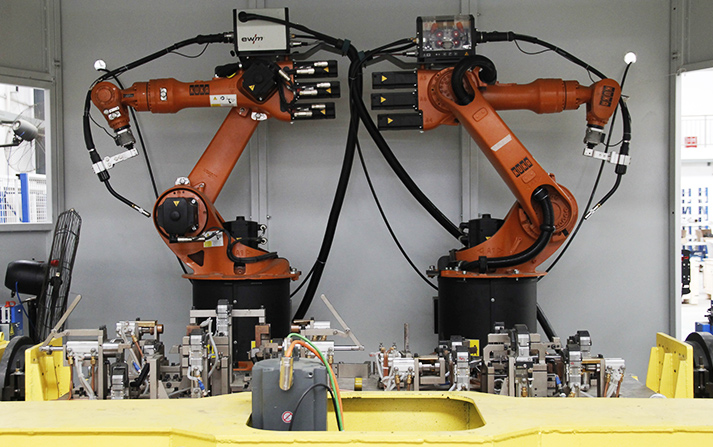

Modern arc welding robots use multi-axis coordinated motion, allowing the robot, external axes, and welding positioners to move as one system. This is critical in automated arc welding, where even small deviations can lead to undercut, lack of fusion, or excessive spatter.

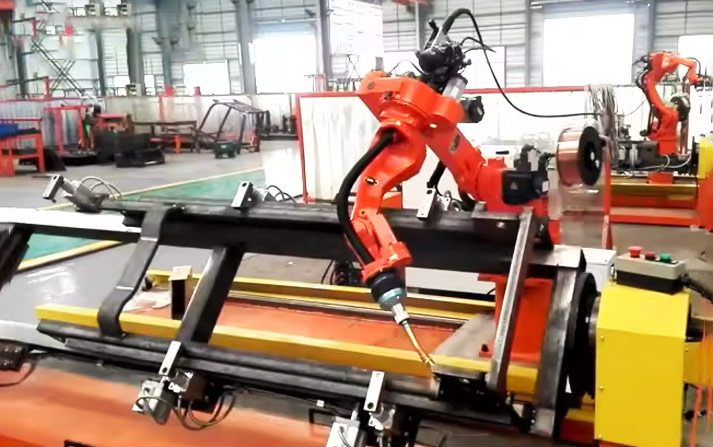

Path intelligence also plays a key role. Robots must adapt to:

Long weld seams

Complex joint geometries

Repeated thermal distortion

Without precise motion planning, arc welding automation quickly loses its advantage over manual welding.

The second core technology integrated into arc welding robots is welding process control.

This is where automated arc welding truly differs from traditional robotic handling. The system must actively manage:

Welding current and voltage

Heat input and penetration

Arc stability during speed changes

Wire feed coordination

In professional arc welding automation, robots are tightly connected to intelligent welding power sources. Together, they form a closed-loop system capable of responding to real-time welding conditions.

Advanced arc welding in robotics setups may also integrate:

Arc voltage control (AVC)

Seam tracking sensors

Adaptive parameter adjustment

These technologies ensure consistent weld quality even when part tolerances vary—one of the biggest challenges in industrial welding.

Individually, motion control and process control are powerful.

But the real value of arc welding robots comes from how tightly these technologies are integrated.

Poor integration leads to:

Stable motion but unstable welds

Correct parameters but incorrect torch positioning

High-speed movement with inconsistent penetration

Well-designed arc welding automation systems treat the robot and welding process as a single unit. This is why system integration expertise matters just as much as robot selection.

Many manufacturers assume buying a robot equals automation.

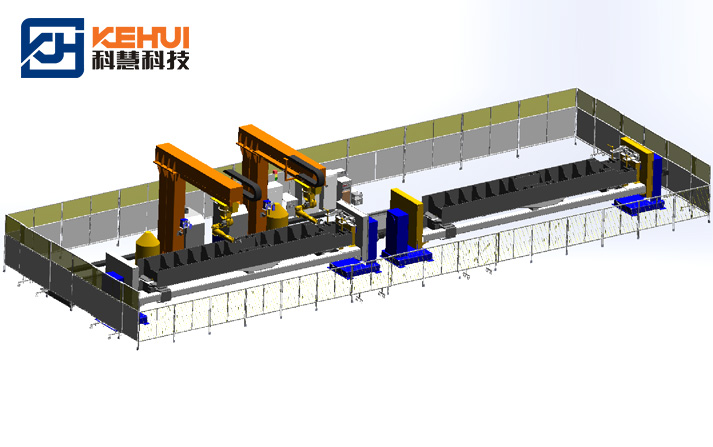

In reality, automated arc welding succeeds only when motion control, welding physics, sensors, fixtures, and software are engineered together.

This is the core of modern arc welding in robotics:

Robots follow intelligent paths

Welding systems actively control the arc

Integration ensures repeatability across shifts and operators

When these two technologies are fully synchronized, arc welding robots deliver what manufacturers actually need: stable quality, predictable output, and lower long-term cost.

So, which two integrated technologies do arc welding robots use?

The answer is clear:

Robotic motion control with path intelligence

Welding process control with active arc management

Together, they form the foundation of reliable arc welding automation.

Understanding this integration is the first step toward building or choosing a truly effective automated arc welding system.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com