+86 15633683072

When manufacturers talk about welding automation, the conversation often starts with robots.But successful projects are not driven by robots—they are driven by robotics integration.

The real challenge is not motion, but how welding, fixtures, material flow, sensors, and control logic work together as a single system. That is why choosing the right welding system integrators has a far greater impact than choosing a robot brand.

This article focuses on how to identify a capable integration partner by looking at system-level engineering, not marketing promises.

Robotics integration is not something you buy off the shelf.

It is an engineering process that turns welding know-how into repeatable production.

A strong integration partner understands how to connect:

1. Welding procedures and metallurgical requirementsThis is why experienced welding system integrators focus more on process stability than robot speed.

If an integrator cannot explain how the system behaves after thousands of weld cycles, they are not thinking like a manufacturer.

Many factories already use robotic assembly systems, but welding introduces very different challenges.

Heat distortion, joint gaps, inconsistent parts, and spatter are realities that cannot be ignored.

An experienced robotic welding system integrator designs robotic assembly systems that account for these factors from the beginning.

This includes:

1. Adaptive torch angles for long seams

2. Controlled heat input across multi-pass welds

3. Fixture designs that balance accessibility and rigidity

4. Seam tracking strategies for real-world part variation

This level of engineering separates true welding system integrators from general automation suppliers.

A professional welding system integrator does not start with robot models.

They start with weld behavior.

Key indicators of a strong partner include:

1. Clear understanding of weld defects and their causes

2. Ability to tune parameters across different materials and thicknesses

3. Experience integrating sensors into closed-loop control

4. Proven methods to stabilize quality across multiple shifts

Reliable welding automation integrators design systems that reduce dependency on operator skill while maintaining weld integrity.

Modern manufacturing demands flexibility.

That flexibility must be built into the robotics integration strategy.

An advanced automated welding system integrator considers:

1. Product changeover time

2. Fixture modularity

3. Parameter switching through software

4. Expansion paths for future automation

Well-designed systems allow robotic assembly systems to handle multiple part variants without major retooling—critical for manufacturers facing fluctuating demand.

True welding automation integrators do more than connect equipment.

They manage:

1. Robot motion and synchronization

2. Welding power source behavior3. Positioner coordination

4. Fault detection and recovery

5. Production data and traceability

An experienced automated welding system integrator delivers systems that can diagnose issues early, minimize downtime, and maintain consistent output.

This system-level control is what turns automation into productivity.

A robot supplier delivers hardware.

An automated welding systems integrator delivers production capability.

The difference is clear on the shop floor:

1. Shorter commissioning time

2. Faster ramp-up to full production

3. Lower scrap and rework rates

4. Easier operator training

Manufacturers working with skilled welding system integrators often discover that long-term operating cost matters far more than initial investment.

No two factories are the same.

That is why robotics integration cannot be completed remotely.

Professional automated welding systems integrator teams provide:

1. On-site installation and debugging

2. Real-part welding trials

3. Parameter optimization under production conditions

4. Operator and maintenance training

Without on-site involvement, even well-designed systems fail to reach their potential.

We have worked as a welding system integrator since 1994, focusing exclusively on welding automation for manufacturing industries worldwide.

Our approach as an automated welding systems integrator is simple:

1. Start from the weld, not the robot

2. Design robotic assembly systems around real parts and real tolerances

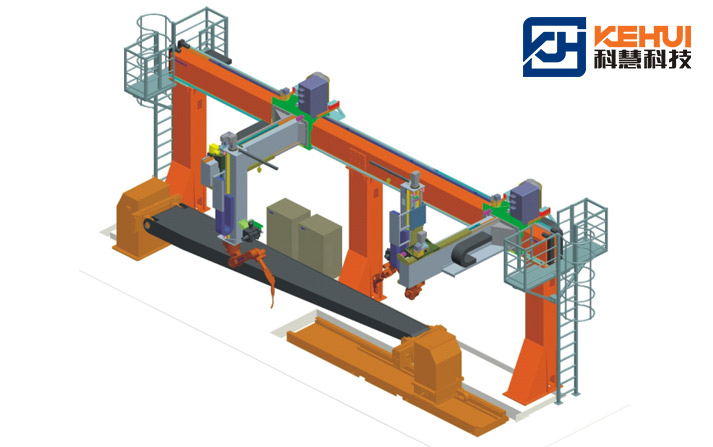

3. Build fixtures, positioners, and controls as one integrated solution

4. Support customers with on-site engineering and long-term optimization

Over decades of projects, we have learned that reliable welding automation is not about complexity—it is about correct integration.

Manufacturers choose us because we deliver systems that run reliably, not just systems that look good during acceptance.

As an automated welding integrator, we provide:

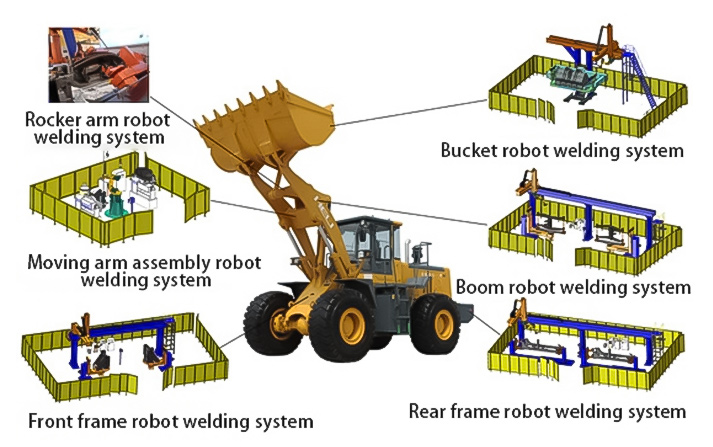

1. Custom robotic welding workstations and full production lines

2. Industry-specific integration experience

3. Engineering teams that travel on-site for installation and commissioning

4. Solutions designed for long-term stability and scalability

If you are evaluating robotics integration partners and want a team that understands welding as a manufacturing process—not just an automation task—we are ready to support your next project.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com