Orbital welding is an automated welding technology that is widely used in high-quality welding operations in pipes, tube sheets and other fields. In orbital welding, there are many different types of technologies and methods, each with its own unique characteristics and applicable scenarios. Below we will introduce several common orbital welding technologies.

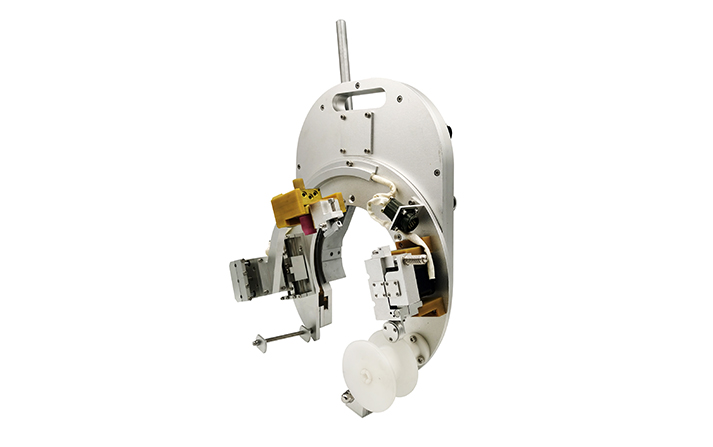

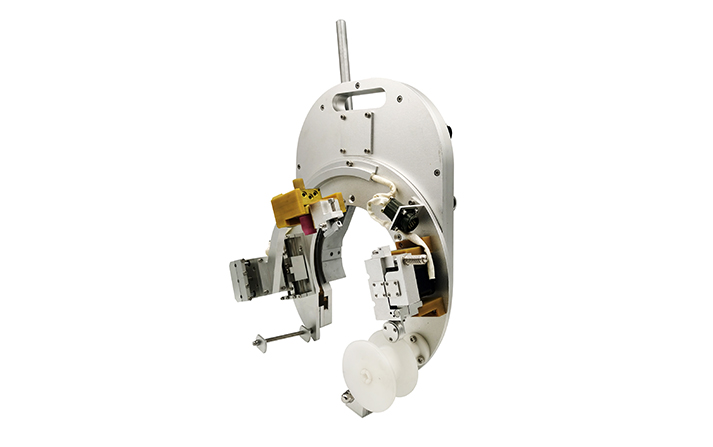

1. Traditional orbital welding:

Traditional orbital welding is the most basic orbital welding technology. It uses a specially designed orbital system, combined with a welding power source and welding head, to achieve automated welding of pipes or tube sheets. Traditional orbital welding is suitable for welding operations of large pipes or tube sheets, and can achieve an efficient and stable welding process.

2. Pulse argon arc orbital welding:

Pulse argon arc orbital welding is a high-end

automated orbital welding technology that uses pulse current and control systems to achieve fine control of the welding process. Pulse orbital welding can effectively control the welding heat and reduce the heat-affected zone, thereby improving the welding quality and stability, and is suitable for scenarios with high welding quality requirements.

3. CNC orbital welding:

CNC orbital welding is an intelligent welding technology that uses a computer control system to achieve precise control and monitoring of the welding process. CNC orbital welding can perform automated welding according to preset parameters, has a high degree of repeatability and consistency, and is suitable for mass production and high-precision welding operations.

4. Laser orbital welding:

Laser orbital welding is a high-energy-density welding technology that uses laser beams to melt and join welding materials. Laser orbital welding has the advantages of fast welding speed, small heat-affected zone, and high weld quality. It is suitable for scenarios with high welding speed and quality requirements, such as aerospace, automobile manufacturing and other fields.

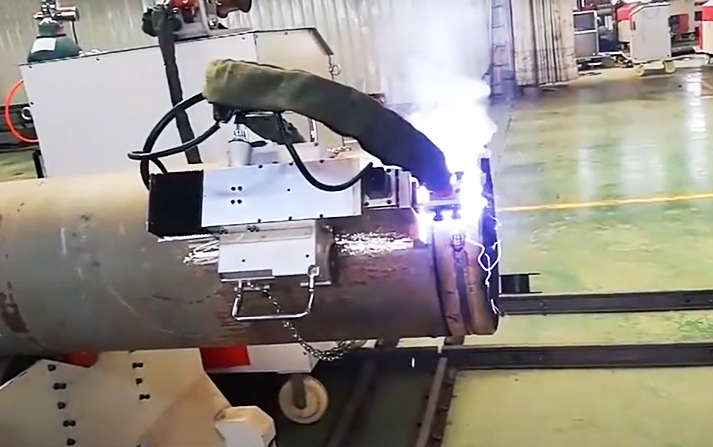

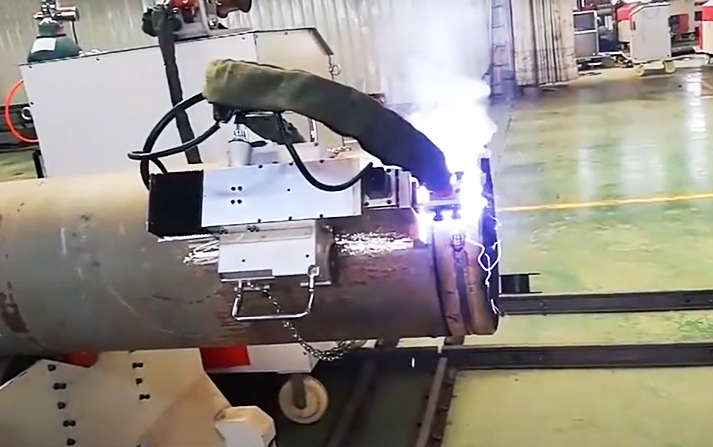

5. Plasma orbital welding:

Plasma orbital welding is a technology that uses plasma arc for welding. It has the characteristics of high energy density and small heat input, and is suitable for welding operations with high material requirements. Plasma orbital welding can achieve high-quality welding and is suitable for welding stainless steel, aluminum alloy and other materials.

To sum up, different types of orbital welding technologies have their own characteristics and are suitable for different welding scenarios and requirements. Choosing a suitable orbital welding machine can improve welding efficiency, quality and stability, and provide reliable technical support for the smooth progress of engineering projects.