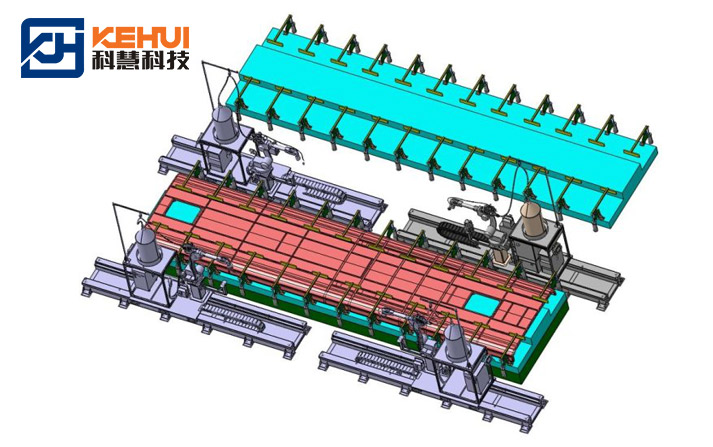

Automobile Body Production Line Welding Fixtures

Automobile body production line welding fixtures are used for welding of new car models, including frame assembly (large floor assembly), left and right side assembly, top cover assembly and door cover opening and closing parts assembly welding. Accurate and reliable positioning, with sufficient structural strength and rigidity, not easy to deform. Excellent process performance, easy assembly of parts, convenient assembly removal, and sufficient operating space. The design of the whole set of fixtures includes the rear wheel package area, side area, rear bumper area, and overall assembly area of the body.