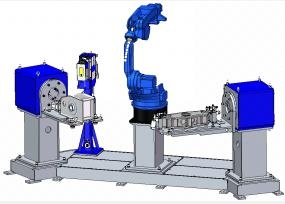

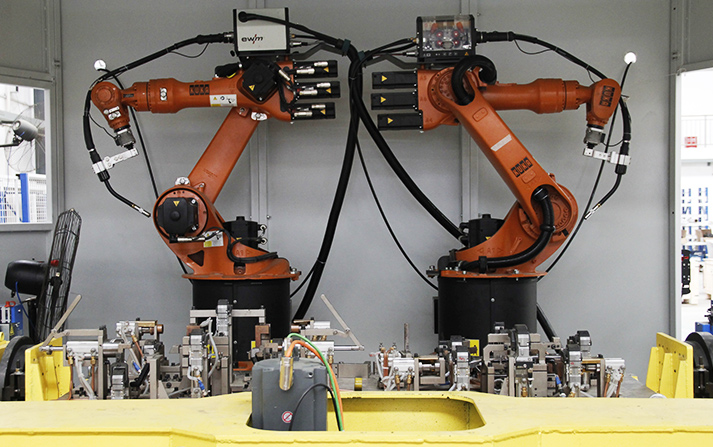

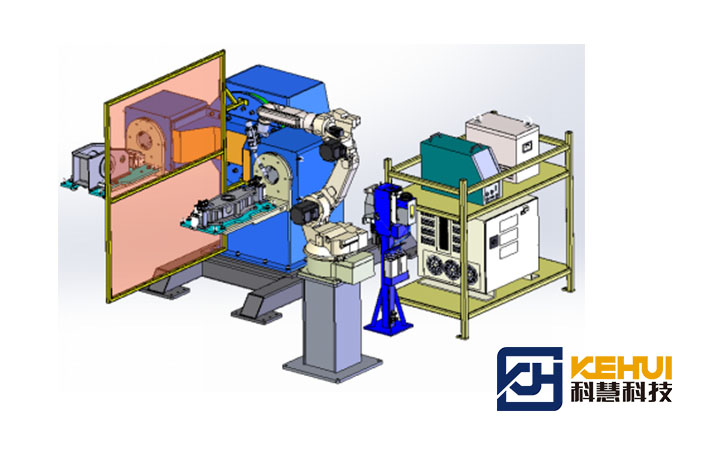

Automotive Body Welding Automated Manufacturing Solutions

Automotive body welding automated manufacturing solutions refer to the comprehensive production line that completes the automobile frame and its floor line through welding process, usually including fixtures, positioning support system, reciprocating transmission equipment and automatic welding equipment. According to the body, it is roughly divided into body side assembly line, body door cover assembly line, floor assembly line, body welding main line, etc., and each part has corresponding main line, sub-line, left and right symmetric line and independent island.