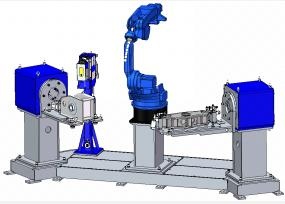

Dump truck compartment frame collaborative robot welding solution

The dump truck compartment and frame collaborative robot welding solution can be laid out according to the actual situation. The frame parts are welded using a robot walking mechanism and a double-station configuration, in conjunction with a flip positioner and fixtures. The side panel welding layout of the compartment adopts a straight-line arrangement, with six sets of hoisting robot welding systems and an assembly line operation method. It is suitable for mass production of products and welding of workpieces with many welds and non-centralized positions.

Application:

The dump truck compartment and frame collaborative robot welding solution is suitable for dump truck front axle welding, front bracket welding, middle bracket welding, rear bracket welding, balancer welding, and compartment box plate automation welding tasks. It is also widely used in welding tasks in the manufacturing fields of bicycle accessories, electric vehicle accessories, agricultural machinery, engineering machinery, auto parts, sports equipment, medical equipment, etc.