+86 15633683072

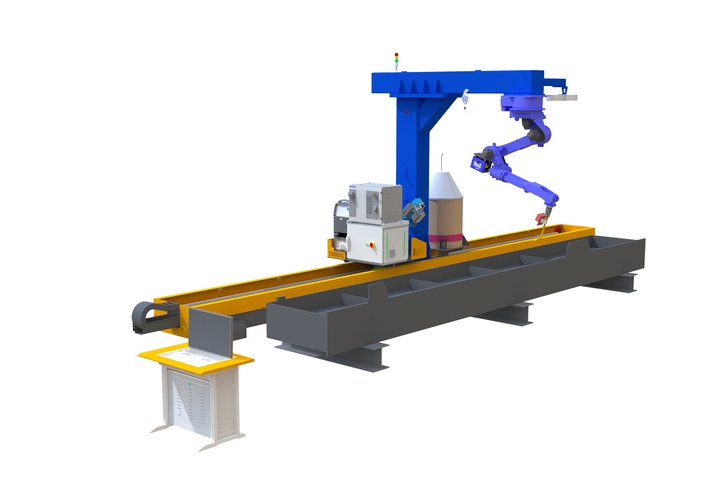

The main functions of a non-teaching programming robotic welding system:

1. Import 3D models: Supports common 3D software formats. STEP , supports SolidWorks , ProE , Inventor , UG , TEKLA Common mechanical 3D software.

2. Select the required weld and process: Supports manual selection of welds and manual adjustment of welding posture as needed; supports welding processes. Custom.

3. Click Start: The system instructs the industrial camera to automatically take pictures, identify the weld positions on the actual workpiece, match and compare them with the 3D drawings, automatically correct the actual weld positions, and the system background will automatically plan a safe obstacle avoidance path and control the robot to execute it. The entire robot movement... The path can be adjusted automatically to achieve the optimal path, and then the welding work can be performed.

Operating environment of H beam no programming required robotic welding systems:

1. Altitude within 1500 meters .

2. The ambient temperature is between 0℃ and +45℃.

3. Ambient humidity: 20-80% RH (non-condensing).

4. The usage location should be free from explosive, dusty, or corrosive media that could seriously affect the use of the equipment , such as toxic gases or steam.

Vapor, chemical deposits, mold, etc.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com