+86 15633683072

| Voltage (3-Phases 50/60Hz) | 220/380V |

| Rated Input Power | 13.9kw |

| Rated input capacity | 14KVA |

| Welding Current Setting Range | 8~400A |

| Filler Wire Speed | 0~1500mm/min |

| Welding speed | 50—150mm/min |

| Capacity of Internal Memory | 100 Programmer |

| Rated load sustained rate | 60% |

| Rated welding voltage | TIG welding 22.6V |

| The rated voltage no-load | 70V |

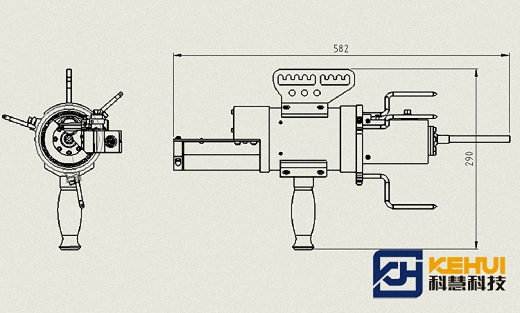

| Weldable tube diameter | 12—80mm |

| Weldable wall thickness | 1—6.5mm |

| Tube biggest stretch out length | 8mm |

| Tube biggest indentation length | 2mm |

| Current up time | 0.1—20S |

| Tungsten pole adjustable Angle | <45° |

| Pulse frequency | 0.5—500HZ |

| Cooling water pressure | 1.2㎏.f/m㎡ |

| Argon gas flow | 8—12L/min |

| Welding Speed | 0.5~5rpm |

| Wire Dia. | ¢0.8 |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com