+86 15633683072

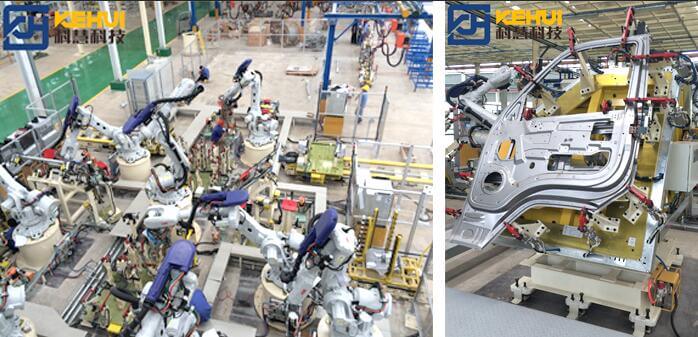

The fixtures are used for fixed spare parts. It ensures the correct relative position during the production process. Workpeice deformation can be prevented. Especially in mass production, the fixtures guarantee great welding quality.

2.High welding precision of the general car body, easy operation.

Spare parts of clamping mechanism uses materials of same mechanical performance. When profile positioning blocks has welding pliers guiding function, it adopts anti-magnetism stainless steel materials with great insulation. When welding pliers does welding, fixtures parts surrounded by pliers uses anti-magnetism stainless steel as well. It guarantees the manufacturing precision and stability of the car general body.

3. Low labor intensity, high production efficiency.

The welding fixture can quickly locate the parts. The parts are easy to install and labor-saving. It effectively reduces the heavy manual labor when the parts are installed and positioned. High-efficiency welding fixtures are used. It leads to less assembly time. Labor efficiency of automobile manufacturing has been fundamentally improved. Meanwhile, it is also conducive to the safe management of welding production.

4. Low cost of body-in-white manufacturing.

Reduce the man-hours required for assembly and welding, increase production efficiency, and reduce the skill requirements of workers in the welding production process, improve the quality of welding, reduce a large amount of rework waste, simplify the production process as a whole, and shorten the manufacturing cycle of the entire body-in-white , so that the cost of the body-in-white is greatly reduced.

5. Easy to assemble and disassemble, short product renewal cycle.

The fixture adopts integral or combined structure. It is convenient to assemble and disassemble. Strong flexibility makes it convenient for customers to replace other products. It leads to short preparation cycle of product remodeling. (just modify the software and necessary fixtures, etc.) The corresponding equipment investment is hugely reduced.

6. Easy equipment inspection and maintenance, complete after-sales system.

KEHUI is a new three-board listed company with a complete after-sales system. The product components are standardized and modularized as much as possible. Regular inspections or parts replacement operations are simplified. It improves the maintainability of the equipment. The engineers will be dispatched for on-site coordinate and guide the installation and commissioning. Comprehensive technical services and materials will be provided as well.

The fixtures are installed on a common substrate platform. After the trial production is finished, the upper part of the fixture can be removed. The lower substrate can still be used in the next new model fixtures. It greatly saves the automobile manufacturer. Capital investment.

Convenient positioning technology -

The positioning pin for automobile body parts adopts a sliding structure. It is different from the manual loading form. The structure is convenient to operate in the field. The positioning pin cannot be lost. The welding efficiency is greatly improved.

Manual pressing mechanism -

The fixture can be manually pressed. The clamping mechanism is designed by the dead point fixing principle of the four-bar mechanism. The pressing force is increased. The operation is convenient and reliable.

Complete line automation integrated control technology -

The entire production line combines the applications with higher level of design and integrated equipment. They include non-standard special equipment applications, logistics transportation applications, non-standard tooling design applications, online inspection design applications.

Flexible design of welding fixtures -

The flexible system of this product can meet the requirements of different vehicle parts and different batches of upper parts. It realizes the welding function on one fixture. The fixture is easy to switch during the upper part process. It saves the footprint space of the equipment.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com