+86 15633683072

1. High degree of automation, strong flexibility, safety and reliability

Can install various positioning workpiece or clamping mechanism, have linkage control interface and corresponding self-protection function, centralized control and mutual coordination work.It can adjust quickly according to the change of manufacturing task and production environment and adapt to all kinds of production tasks.

2. Carry welding tongs with inner transformer, which is efficient and stable in welding quality

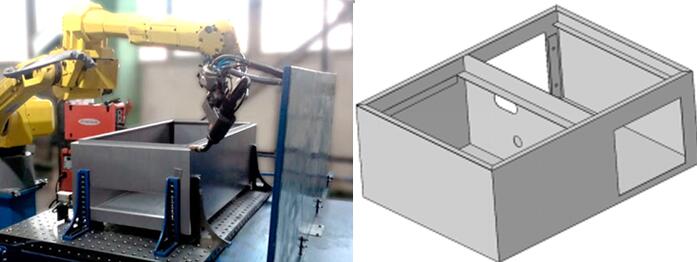

According to the frame size of the top skin of each vehicle, the common locating point was found.The clamping unit is switched with the tooling because of the big difference of vehicle types.Positioning precision is high (± 0.25 MM), to ensure welding quality, spot welding speed has matched the production line, at the same time according to full reliability.

3. Adjustable welding speed, stable quality and beautiful welding seam

The operation speed of welding can be adjusted, with good structural stiffness, effectively ensuring fast welding. The advantage of fast servo rotary speed is more conducive to cross welding and reduce the welding deformation of workpiece.The multi-point positioning of section distance can be completed quickly, and the 24-hour continuous "unmanned production" can be realized.

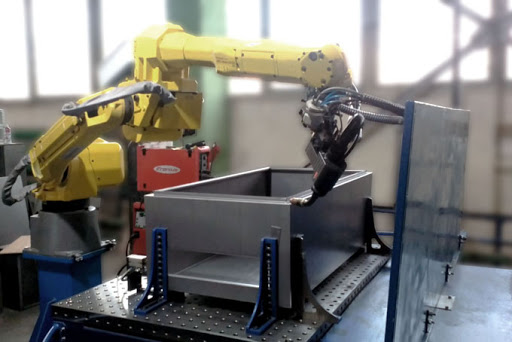

4. Small installation area and large working space

Improve equipment utilization, reduce equipment quantity and workshop floor space.Be able to arrange the processing of required parts timely according to the welding operation, so as to reduce the inventory of blank and finished products, thus reducing the corresponding funds, sites and so on.

| power | 3 phase current 380±10% |

| rated power | 50kVA |

| Secondary maximum short circuit current | 15000A(5% Under the load) |

| The electrode is most pressurized | 3000N |

| Depth of welding tongs | 350mm |

| Electrode travel of welding tongs | 120mm |

| robotic system | KR150-2 |

| Pneumatic system pressure(MPa) | 0.6 |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com