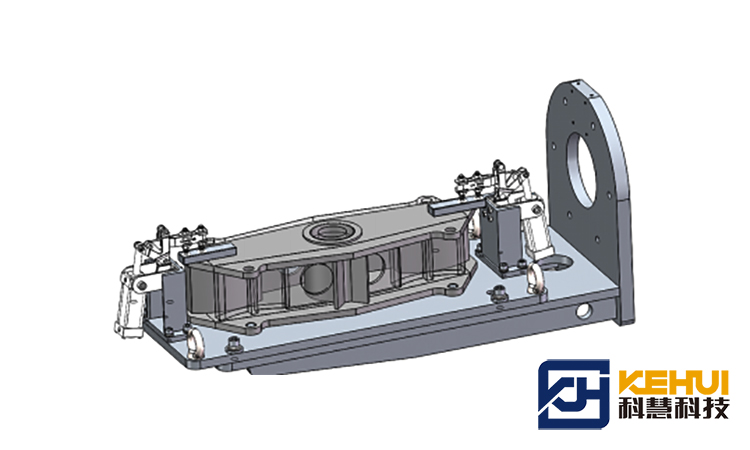

1.Fixtures

the fixtures adopts automatic clamping and positioning, ability to match with handling robot information. Simple structure, convenient operation, high efficiency of assembly, and stable clamping force.

2.The times speed conveying line

Adopting double-layer times speed conveying, which is divided into upper and lower layers, and the self-returning is formed. The workpiece is positioned on the conveying chain plate by the location pin, and a secondary positioning mechanism is arranged in the transfer robot connection area to automatically complete the precise positioning of the chain plate.

3.Robot slide platform

Driven by servo motor + precision planetary reducer, free programming. It adopts domestic famous brand reducer, guide rail, slider, rack and pinion, which has high walking precision, meets welding requirements and has long service life.

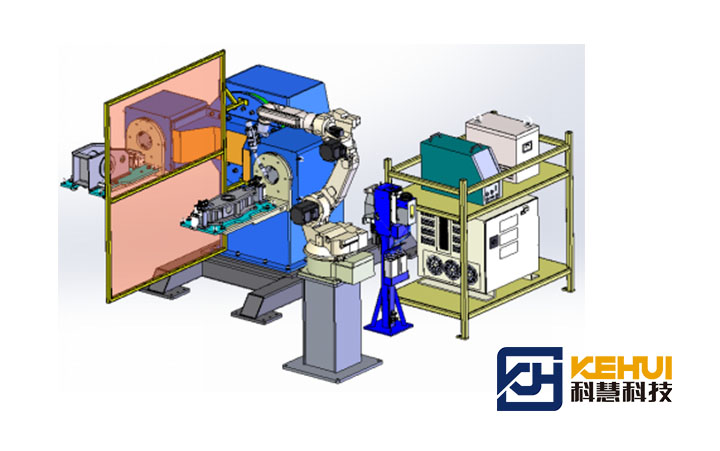

4.Conveying line of robotic loading and unloading line

Mainly includes loading and unloading robot, robot control cabinet, robot teaching pendant, robot slide platform, compatibility automatic gripper, times speed chain logistics line, plate chain type of logistics line and control system.

5.The control electric of welding production line

The programmable program control system is adopted, and the main control part is controlled by PLC system. With "manual" and "automatic" optional features,

With: reservation, power on/off and indication, emergency stop button, with mechanical anti-collision, servo anti-collision, power status detection, interference field inspection and other functions.

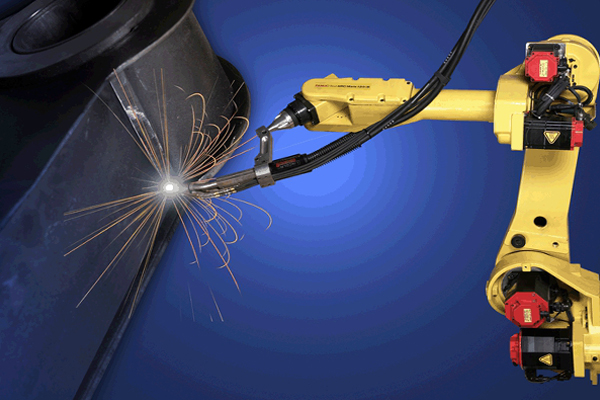

1. The core components are imported from Japan, with excellent technical performance:

1. The core components are imported from Japan, with excellent technical performance: