+86 15633683072

As a manufacturer specializing in automated pipe welding systems, we often talk to customers who have already tried multiple solutions. Many of them come to us after realizing that choosing the wrong stainless steel pipe welding machine can cost far more than the machine itself—through rework, unstable weld quality, and wasted production time.

From our experience, a reliable stainless steel pipe welding machine is not about having more features, but about matching the welding process to real production conditions. This is exactly where many pipe welding companies struggle.

Stainless steel is unforgiving. Heat input, shielding quality, and repeatability all matter.

In real production, manual welding or semi-automatic setups often fail to control these variables consistently.

That’s why more manufacturers are replacing traditional setups with an ss pipe welding machine designed for automatic operation. A well-designed ss pipe welding machine keeps the arc stable, protects the weld pool, and eliminates human variation—especially critical for thin-wall or high-purity stainless pipes.

From our factory’s perspective, the biggest challenge is not welding stainless steel once, but welding it the same way, hundreds of times per day.

In modern workshops, efficiency is no longer optional. That’s where automatic pipe welding equipment changes the game.

Compared with manual processes, automatic pipe welding equipment allows:

Consistent heat input across every weld

Repeatable welding parameters stored in the system

Reduced dependence on highly skilled welders

Higher pass rates during inspection

When customers upgrade to an automatic steel pipe welding machine, the first thing they notice is not speed—it’s stability. Weld seams become uniform, penetration is controlled, and rework drops sharply.

As a manufacturer, we don’t design machines in an office—we design them around real welding tests.

Every ss pipe welding machine we produce is developed around:

Actual stainless steel pipe samples

Different pipe diameters and wall thicknesses

Continuous welding trials under factory conditions

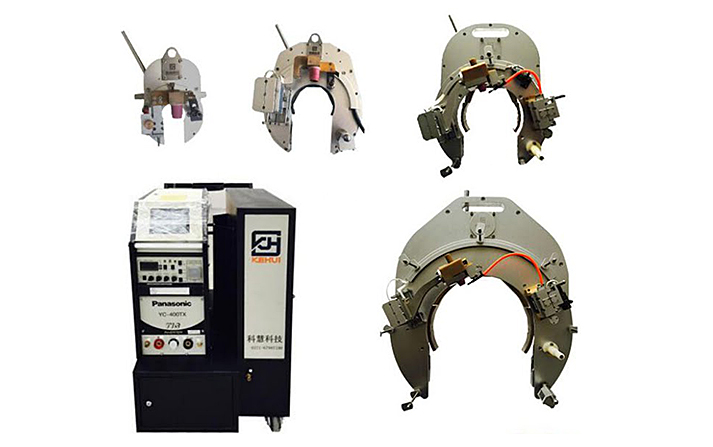

A professional stainless steel pipe welding machine must handle long duty cycles, precise torch positioning, and accurate gas control. This is why our systems integrate servo-driven motion, closed-loop arc control, and programmable welding sequences.

For many customers, switching to an automatic steel pipe welding machine is the turning point where quality finally becomes predictable.

There’s a reason global buyers increasingly source from a China stainless steel pipe welding machine manufacturer.

From our side as a factory, the advantages are clear:

Complete in-house production: machining, assembly, testing

Fast customization for different pipe standards

Mature supply chains for welding power sources and motion components

A well-built China stainless steel pipe welding machine today is not a low-end alternative—it’s a fully engineered industrial solution that many international pipe welding companies now rely on for long-term production.

Many customers ask us whether an automatic steel pipe welding machine is really worth it.

Our honest answer:

If you only weld occasionally, manual welding may be enough.

If welding is part of your daily production, automation is unavoidable.

An automatic steel pipe welding machine doesn’t just increase output—it standardizes quality, shortens training time, and makes scaling possible. That’s why serious pipe welding companies eventually move toward automation, even if they start small.

We don’t just sell machines—we help customers rethink how welding fits into their production line.

Whether it’s a compact ss pipe welding machine for workshop use or fully integrated automatic pipe welding equipment for production lines, our focus is always the same:

Stable welding performance

Simple operation

Long-term reliability

That’s how a stainless steel pipe welding machine should work—not in theory, but on the factory floor, every single day.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com