+86 15633683072

When people talk about orbital welding technology, they often picture a machine that “just goes around the pipe and welds automatically.”

From a factory perspective, that description is far too simple.

After years of building and testing orbital systems, we’ve learned that orbital welding technology is not one single invention—it’s a combination of motion control, arc stability, heat management, and process logic working together under real industrial conditions.

This article explains how the technology actually works, why the tools matter, and how manufacturers like us design equipment that performs beyond brochures.

At its core, orbital welding technology exists to control what human hands cannot do consistently over time.

In manual pipe welding, quality fluctuates due to:

Hand travel speed

Torch angle changes

Arc length variation

Fatigue over long shifts

Modern orbital welding technology removes these variables by locking them into programmable parameters. Once the welding head starts moving, every millimeter of motion follows a predefined logic.

That’s why experienced orbital welders manufacturers focus less on “automation speed” and more on repeatability and thermal stability.

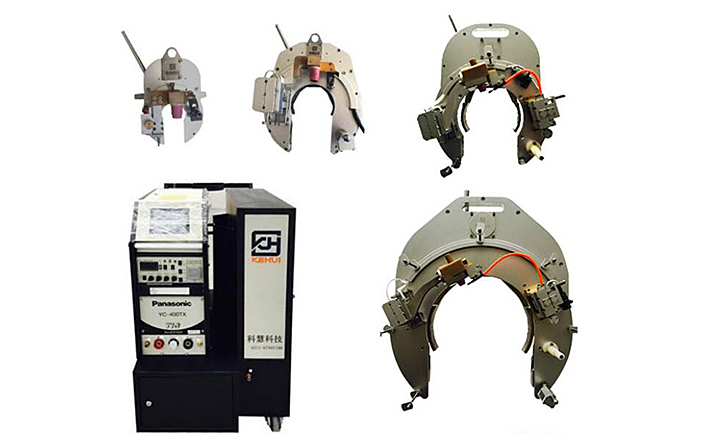

Many users focus on power sources but overlook orbital welding tools, which directly define welding performance.

From our production floor, the quality of orbital welding tools determines:

Arc stability during rotation

Heat consistency at overlap points

Shielding gas coverage inside and outside the joint

Poorly designed tools introduce vibration, backlash, or uneven pressure—problems no software can fix.

This is why professional orbital welders manufacturers invest heavily in:

Precision gear systems

Balanced welding head structures

Durable clamping mechanisms

In real-world welding, good orbital welding tools matter as much as current settings.

Many companies market machines as orbital systems, but true orbital welding technology goes beyond hardware.

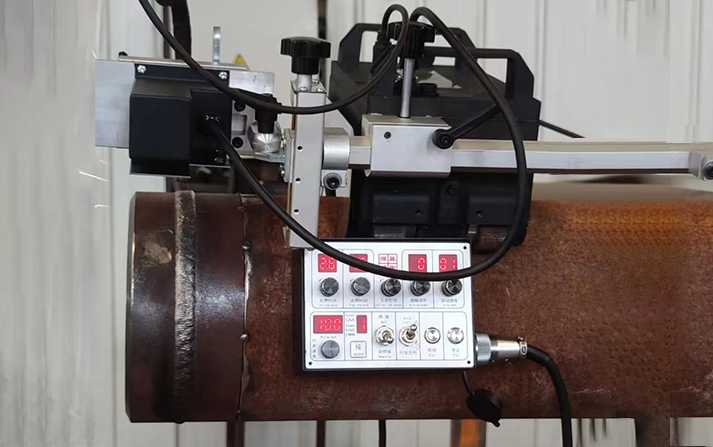

As a manufacturer, we see orbital systems as three integrated layers:

Mechanical structure

Control software

Welding process database

Companies operating under names like orbital welding equipment ltd often fail when these layers are developed separately.

In our factory, welding heads, controllers, and software are tested together under real pipe conditions. This system-level thinking is what separates a usable machine from the best orbital welding machine in production environments.

One misunderstood aspect of orbital welding technology is material behavior.

Carbon steel, stainless steel, and high-alloy materials respond very differently to heat input. Advanced orbital systems adjust:

Pulse frequency

Travel speed by position

Arc length dynamically

This adaptability is not optional—it’s essential.

That’s why experienced orbital welders manufacturers build material logic directly into their control systems instead of relying on operator judgment.

Without this, even the most expensive orbital welding tools will struggle to deliver consistent results.

From a factory standpoint, the best orbital welding machine is not the one with the most features—it’s the one that welds the same joint well on day 1 and day 1,000.

In our internal evaluations, the best orbital welding machine consistently shows:

Stable arc during 360° rotation

Minimal weld overlap defects

Reliable gas shielding throughout the cycle

Simple, repeatable parameter selection

This is why serious buyers evaluate machines based on long-term consistency, not demo welds.

Across industries, we’ve seen more workshops transition once they realize what orbital welding technology actually delivers:

Predictable weld quality

Lower dependency on individual skill

Easier quality documentation

Faster training cycles

As production scales, manual TIG becomes a bottleneck. Orbital systems don’t just weld—they stabilize the entire manufacturing process.

That shift is why global demand for advanced orbital welding tools and systems continues to grow.

As a factory developing orbital systems every day, we don’t treat orbital welding technology as a finished product.

We see it as a constantly evolving platform—one that must adapt to new materials, tighter tolerances, and higher quality expectations.

Whether customers work with an orbital welding equipment ltd brand or directly with orbital welders manufacturers like us, the real value lies in how well the technology fits actual production conditions.

And that—not marketing language—is what defines the best orbital welding machine.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com