+86 15633683072

Most people search orbital welding procedures because something already went wrong: welds look good outside but fail X-ray, pipes warp, or production is too slow.

From our factory experience building automated pipe welding lines, a stable weld is not magic—it’s a workflow. A repeatable one. Below is how we actually run projects using an orbital tube welding machine and trained operators.

Good orbital welding procedures start before the arc.

In our shop we insist on:

Precision cutting – tube squareness within 0.1 mm

Bevel prep – thin wall often needs zero-gap fusion

Cleaning – acetone wipe + oxide removal

Material check – stainless grade confirmation

If the pipe is dirty, no orbital tube welder can save it.

For pharmaceutical or semiconductor pipelines, preparation is even stricter because of high purity orbital welding requirements. Any oil or oxide becomes contamination.

That’s why our orbital welding system packages include alignment tools and prep guidelines—not just a machine.

Bad alignment kills beautiful welds.

Real orbital welding procedures always define:

Clamp type

Concentricity tolerance

Gap control

Tack-free positioning

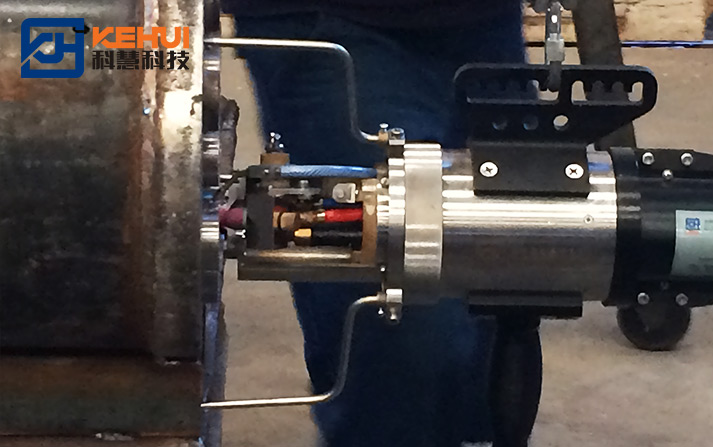

Our closed-loop orbital tube welding machine fixtures hold pipes without tack welding, which avoids internal oxidation—important for high purity orbital welding projects.

Customers often discover their biggest improvement after switching from manual fit-up to automated clamping with an orbital tube welder.

People focus on amperage, but gas control is the real hero of orbital welding procedures.

We set:

Shield gas flow

Back purge timing

Oxygen ppm target

Pre-flow & post-flow

For food-grade or biotech lines, our high purity orbital welding setups require <20 ppm oxygen before arc start.

A professional orbital welding system must maintain gas stability during rotation. That’s why our welding heads use sealed chambers and balanced flow channels.

An orbital tube welding machine without purge stability is just a rotating torch.

Customers always ask:

“What current for 2-inch stainless?”

Real orbital welding procedures don’t use one number. They use curves.

We program in the orbital tube welder:

Start current

Peak current

Background current

Downslope

Rotation speed

Our orbital tube welding machine controllers store parameter libraries for different pipe sizes and alloys.

For thin stainless tubing in high purity orbital welding, we use lower heat input and multi-segment cooling to prevent discoloration and carbide precipitation.

A good orbital welding system remembers good welds so operators don’t reinvent them.

Real factories don’t guess.

Standard orbital welding procedures include:

Visual inspection

Weld bead profile check

Borescope internal check

Pressure test or X-ray

With a calibrated orbital tube welder, weld consistency becomes predictable. Operators stop worrying, inspectors stop rejecting.

That’s the moment automation pays for itself.

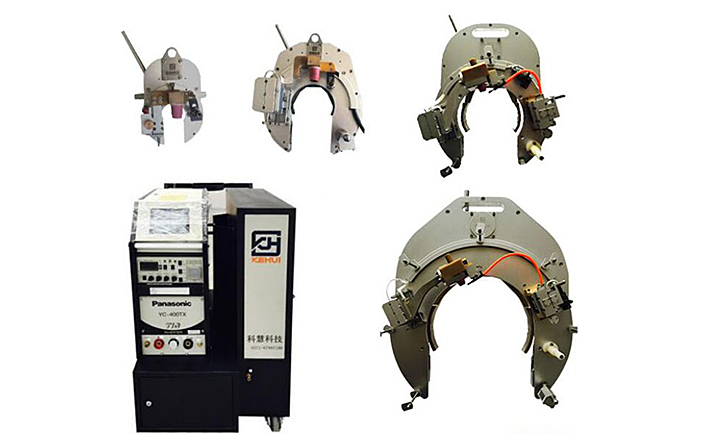

Because we manufacture automated pipe welding equipment ourselves, we don’t just sell an orbital tube welding machine.

We help customers build their own library of proven orbital welding procedures, optimized for their materials, pipe sizes, and production speed.

Our complete orbital welding system includes:

Equipment and fixtures

Process parameter database

Operator training

On-site commissioning

Support for high purity orbital welding projects

Many clients come to us only wanting an orbital tube welder.

They leave with a stable production workflow.

Because in real manufacturing, machines matter—but procedures make profit.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com