+86 15633683072

Every automation project looks stable on acceptance day. The real test begins three months later.

Most manufacturers encounter robotic welding issues and challenges not during installation, but during continuous production. The gap between “demo performance” and “factory reality” is where welding automation either proves its value—or exposes its weaknesses.

Understanding these robotic welding issues and challenges from a lifecycle perspective is essential for building reliable industrial robotics solutions.

Many problems begin long before the first weld arc.

Common early-stage robotic welding issues and challenges include:

Underestimated heat distortion in large weldments

Unrealistic cycle time targets

Ignoring part tolerance variation

Selecting robot models without evaluating process load

At this stage, manufacturers often focus on robot brand or cost. However, successful robotic welding solutions begin with welding procedure validation, fixture stress analysis, and process simulation.

Strong industrial robotics solutions are engineered around welding behavior—not just robot capability charts.

During commissioning, the system runs well under controlled conditions. But once production variability increases, hidden weaknesses appear.

Typical robotic welding issues and challenges at this stage:

Inconsistent arc start under different surface conditions

Wire feed instability after long duty cycles

Minor TCP deviations causing visible weld inconsistency

Spatter buildup affecting sensor reliability

These are not robot hardware failures. They are integration depth issues.

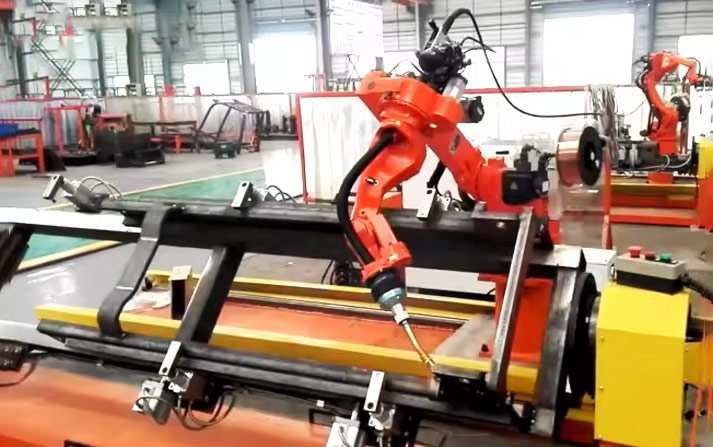

Proper robotic welding integration requires synchronized control between:

Robot controller

Welding power source

Wire feeder

Positioners

Safety systems

Many robotic welding machine manufacturers provide reliable robots, but system-level integration determines whether those robots perform consistently.

When production increases from single shift to continuous operation, new robotic welding issues and challenges appear:

Thermal drift in fixtures

Accumulated mechanical wear in torch mounts

Parameter deviation between shifts

Variation in operator handling of consumables

At this stage, reactive troubleshooting is no longer enough.

Proactive robotic welding solutions include:

Structured maintenance planning

Consumable lifecycle monitoring

Arc stability data tracking

Fixture recalibration protocols

This is where robust industrial robotics solutions demonstrate long-term value.

Arc welding and laser welding introduce different technical risks.

A skilled laser welding robot integrator must manage:

Optical alignment stability

Beam quality consistency

Shielding gas precision

Thermal concentration control

Laser processes tolerate far less deviation than arc welding. Therefore, robotic welding integration in laser systems demands tighter calibration and higher environmental control.

Not all robotic welding machine manufacturers are prepared to deliver full-process laser integration. Choosing the right laser welding robot integrator becomes critical when precision and heat input margins are minimal.

One overlooked area in robotic welding issues and challenges is data visibility.

Without structured data collection:

Arc interruptions go undocumented

Parameter drift remains unnoticed

Maintenance patterns are reactive

Root causes stay hidden

Modern industrial robotics solutions increasingly integrate:

Weld parameter logging

Arc time monitoring

Quality traceability systems

Real-time fault diagnostics

These elements transform robotic welding from mechanical automation into measurable process control.

Many companies approach robotic welding machine manufacturers expecting a turnkey result.

However, manufacturers supply equipment. Performance depends on system architecture.

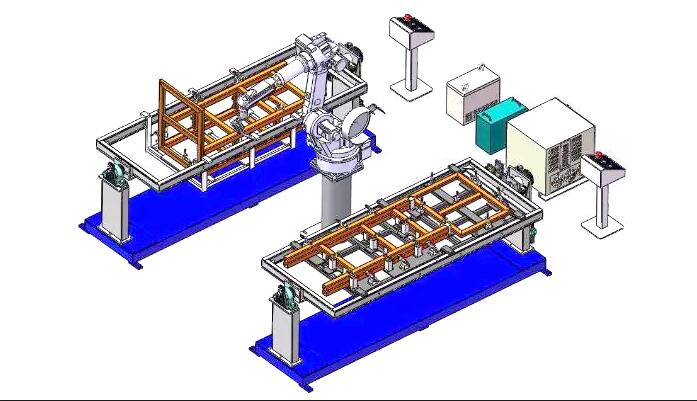

Reliable robotic welding solutions require:

Fixture engineering aligned with weld sequence

Power source selection based on material type

Seam tracking integration when necessary

Multi-robot coordination logic

On-site validation under real production conditions

This depth defines true robotic welding integration.

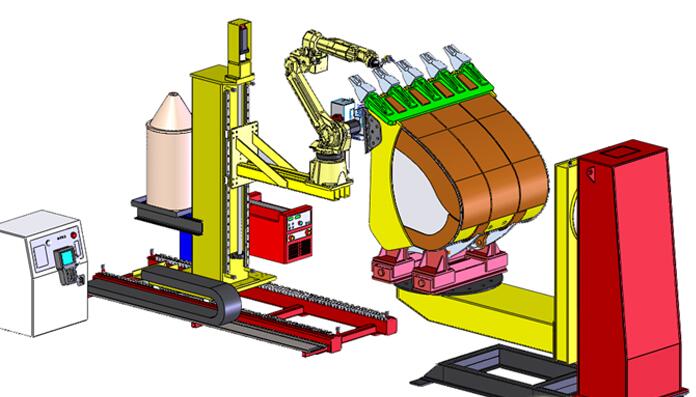

Since 1994, we have specialized in welding-focused robotic welding integration.

We are not simply equipment suppliers among many robotic welding machine manufacturers. We build complete, production-ready industrial robotics solutions designed for real manufacturing environments.

Our approach includes:

Welding process validation before robot selection

Integrated fixture and thermal design

Seam tracking and adaptive correction when required

Arc parameter optimization under production load

On-site installation, commissioning, and training worldwide

We have delivered robotic welding systems to manufacturers across multiple countries, supporting heavy fabrication, structural components, machinery production, and complex welded assemblies.

Most importantly, we design systems to address real robotic welding issues and challenges before they disrupt production.

Automation should reduce uncertainty—not create it.

If your goal is stable output, predictable weld quality, and scalable welding automation, then the strength of your robotic welding solutions depends on the depth of your integration partner.

That is where our experience, built over three decades, makes the difference.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com