+86 15633683072

Many buyers believe that once they purchase a robotic arm for welding, automated welding problems are solved.

In reality, the robotic arm is only one component in a much larger and more complex welding ecosystem.

This misunderstanding is also the reason why many companies buy a robotic welding arm for sale, invest a significant budget, and still end up with unstable welds, long debugging cycles, or even abandoned robot cells.

Let’s break down the reality—from a system integrator’s perspective.

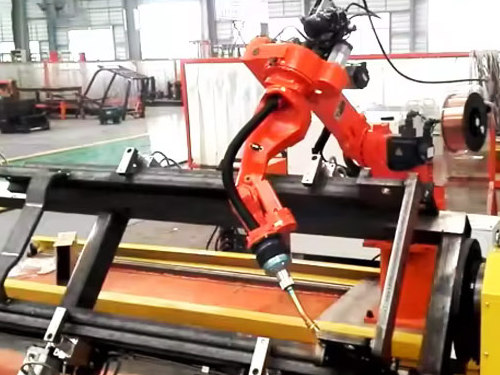

A robotic arm welding machine is responsible for positioning and motion.

It does not decide weld penetration, bead appearance, arc stability, or long-term consistency.

When customers focus only on:

robotic arm for welding brand

robotic welding arm price

payload and reach

they often overlook the elements that actually control welding quality.

You can install the most expensive robotic arm for welding, but if the welding power source and wire feeding system are mismatched, results will be disappointing.

Key integration issues include:

Arc characteristic compatibility with robotic motion

Dynamic wire feeding stability during acceleration and deceleration

Torch cooling capacity for long-duty-cycle welding

Cable routing affecting robot balance and repeatability

Many customers who buy a welding robot arm for sale separately later discover that no supplier takes responsibility for the overall performance.

A robotic arm does not weld—the process does.

One of the biggest myths is that higher robot accuracy automatically means better weld quality.

In real production:

Poor fixtures cause inconsistent joint gaps

Thermal deformation shifts weld seams

Robot repeatability becomes meaningless without part consistency

Even the best robotic arm welding machine cannot compensate for unstable workpieces.

From our experience, fixture design often contributes more than 50% to welding stability—yet it is rarely considered when customers compare robotic welding arm price.

Offline programming and teaching points look perfect on the screen.

Reality is different.

Common issues include:

Plate distortion after tack welding

Assembly tolerances exceeding robot compensation range

Manual re-teaching required for each batch

This is why selecting industrial robot arms for welding without considering seam tracking, sensing logic, and real-time compensation is risky.

A robotic arm for welding follows commands—it does not understand weld quality by itself.

Companies that purchase a robotic welding arm for sale without system integration often face:

Endless parameter tuning

Blame-shifting between robot and welding power suppliers

Long production downtime

Lack of process documentation and standards

At that point, the initial low robotic welding arm price no longer looks attractive.

When selecting industrial robot arms for welding, the real question should be:

“Who is responsible for the final weld quality?”

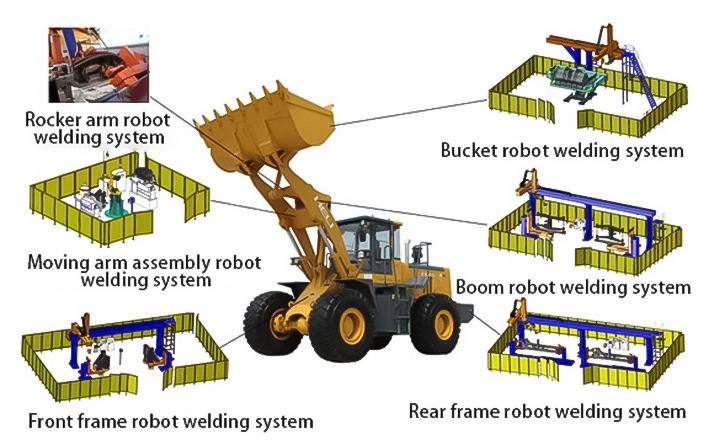

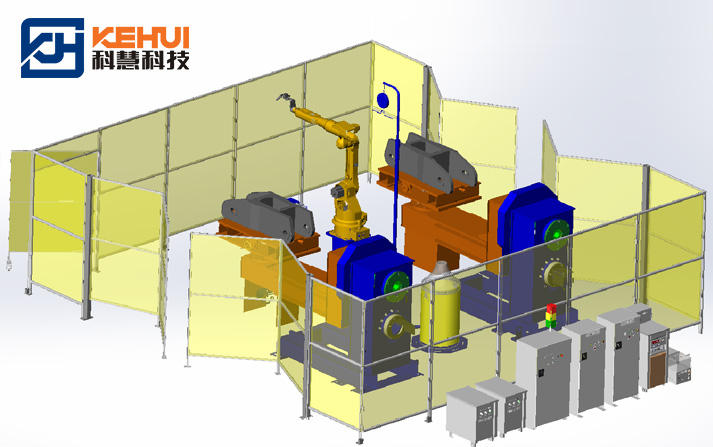

A reliable welding system must include:

Proper robotic arm selection

Welding process matching

Fixture and positioner design

Safety and fume extraction

On-site commissioning and training

Without system responsibility, even the best robotic arm for welding becomes an expensive experiment.

This is where experienced automation integrators step in.

A professional integrator does not sell a robotic arm welding machine.

They deliver repeatable welding results.

We are an automatic welding system integrator founded in 1994, specializing in robotic welding workstations and automated welding production lines for manufacturing enterprises worldwide.

What makes us different:

Over 30 years of real welding automation experience

Complete responsibility from robot selection to weld validation

Customized robotic arm for welding solutions based on real parts, not catalogs

Engineers available for on-site installation, debugging, and training

Proven systems running stably in multiple countries and industries

We don’t just offer a welding robot arm for sale.

We make sure the system works on your shop floor—day after day.

Buying a robotic arm for welding is easy.

Building a reliable welding system is not.

If you are evaluating a robotic welding arm for sale, comparing robotic welding arm price, or selecting industrial robot arms for welding, talk to a system integrator who understands welding—not just robots.

That is exactly what we have been doing since 1994.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com